How to Design a Restaurant Kitchen Layout Around a Commercial Griddle

A successful restaurant kitchen comes down to one thing: putting your most important equipment right in the middle of the action. For many high-volume restaurants, that means building the entire workflow around the commercial griddle. Its placement is the difference between a smooth, profitable service and a chaotic mess.

Why Your Commercial Griddle Is the Heart of the Kitchen

Stop thinking of your griddle as just another appliance. It's the central hub of your entire hot line. For diners, burger joints, and breakfast spots, the commercial griddle sets the rhythm for every single ticket that comes through. Getting this right is the first—and most important—step in designing a kitchen built for speed and efficiency.

Think of it like the quarterback on a football team. Every other move on the line—frying, plating, dressing—depends on what’s happening on that flat top. The griddle cook is calling the plays. When that key piece of equipment is in the right spot, the whole team flies.

The Commercial Griddle's Impact on Kitchen Operations

A well-placed commercial griddle does a lot more than just cook food. It establishes the operational DNA for your kitchen, directly impacting ticket times, how your staff moves, and even food quality. The right layout cuts down on the steps a cook has to take, which means less fatigue and fewer mistakes when you're slammed.

This is especially true for modern kitchen concepts. For example, delivery-only operations live and die by speed. You can see exactly how they build their layouts in our article on what is a ghost kitchen, where the commercial griddle is king for pumping out high volumes of orders.

A strategically placed griddle transforms a cook line from a series of disconnected stations into a cohesive, high-output production engine. It’s the single most important decision for maximizing throughput in griddle-heavy menus.

By anchoring your design with the commercial griddle, you create a workflow that just makes sense. Every other piece of equipment and every prep station is there to support it. The result is a kitchen that's not just faster, but way less stressful for your crew.

To help visualize these ideas, here’s a quick breakdown of the core principles when designing around a commercial griddle.

Griddle-Centric Design Principles at a Glance

| Design Principle | Primary Goal | Impact on Kitchen Flow |

|---|---|---|

| Central Placement | Minimize cook movement and wasted steps. | Creates a natural "command center" where the primary cook can oversee the entire line. |

| Proximity of Support | Keep essential tools and ingredients within arm's reach. | Reduces travel time for the cook, speeding up ticket times and preventing bottlenecks. |

| Logical Workflow | Arrange stations (prep, fry, expo) in a linear or circular path. | Ensures food moves smoothly from raw prep to the finished plate without backtracking. |

| Clear Communication | Position the griddle for a clear line of sight to the expo window. | Improves coordination between the line and front-of-house, reducing errors and remakes. |

Ultimately, a smart layout built around your commercial griddle is a direct investment in consistency and profitability. It’s how you make sure every burger, pancake, and patty melt flies out of the kitchen with maximum efficiency, order after order.

Mastering Griddle-Centric Kitchen Workflow

In a commercial kitchen, every wasted step is wasted money. When your commercial griddle is the heart of the operation, the goal is to make every single movement from your cook count. We're talking about a workflow so tight and intuitive that it becomes second nature.

For years, a common design theory was the "kitchen work triangle," an idea from the 1920s connecting the sink, stove, and fridge. It works great for a home kitchen, but it's too slow for the pace of a busy hot line centered on a commercial griddle. You can discover more insights about the history of kitchen design to see how these foundational ideas have evolved.

From Triangle to Diamond: A Modern Griddle Workflow

Forget the triangle. For a griddle station, you need to think in terms of a work diamond. This isn't just a shape—it's a philosophy. It connects the four crucial points a cook interacts with constantly, putting them all within arm's reach to eliminate wasted motion.

Here are the four points of the griddle work diamond:

- The Commercial Griddle: The main event. This is where the action happens and where your cook’s attention is focused.

- Ingredient Refrigeration: An under-counter or low-boy unit, right next to or under the griddle. It’s stocked with the immediate essentials—burger patties, eggs, cheese, bacon.

- Prep and Tool Zone: The spot with cutting boards, squeeze bottles, spatulas, and seasonings. It must be instantly accessible without the cook even having to turn around.

- Plating and Service Window: The finish line. This is where finished dishes go, positioned right next to the griddle for a seamless handoff.

With this diamond layout, your cook can perform 90% of their tasks by simply pivoting instead of walking. The idea is to build an ergonomic cockpit where everything they need is just one step away, slicing precious seconds off every single ticket.

Putting Workflow Into Practice: The Breakfast Rush

Let's see what this looks like in the real world. Picture a short-order cook getting slammed during a Sunday breakfast service. In a badly designed kitchen, an order for bacon and eggs is a chaotic dance:

- The cook takes three steps to the reach-in cooler for eggs and bacon.

- They walk back to the griddle.

- They turn around completely to grab a spatula from a shared bin.

- After cooking, they take another four steps to the plating window, leaving the griddle unattended.

That’s at least seven unnecessary steps and two full turns away from the cooking surface for just one order. Now, let’s run the same order through the work diamond.

A well-designed griddle station isn't about working harder; it's about eliminating the friction between the cook and the finished plate. Every second saved from wasted movement is a second invested in food quality and ticket time.

In the optimized layout, the cook just pivots. They reach down into the under-counter fridge for eggs and bacon, slap them on the griddle, grab a spatula from a magnetic strip right above the station, and plate the dish on a counter that flows right to the service window. The entire process happens in a tight, efficient space with almost no steps.

The Cumulative Effect of Shaving Seconds

A few saved seconds might not sound like a big deal, but they add up fast. If a cook handles 100 tickets in a shift and you save just 15 seconds of wasted motion per ticket, you've just saved 25 minutes.

That’s enough time to pump out another 15-20 orders. This doesn't just boost your revenue; it dramatically cuts down on cook fatigue. That means fewer mistakes, less burnout, and a better, more consistent plate of food for your customers. Smart restaurant kitchen layout design, built around your commercial griddle, pays for itself with every ticket.

Choosing the Right Commercial Griddle and Where to Put It

Few decisions will shape your kitchen's daily reality more than picking the right commercial griddle and finding its perfect home on the line. This isn't just about buying another piece of steel; it's about choosing the very engine of your hot line. Get it right, and you boost speed, efficiency, and menu potential. Get it wrong, and you create bottlenecks that will haunt every single service.

So where do you start? Your menu. Always, always, always start with your menu. A classic American diner flipping pancakes and eggs all day needs a completely different commercial griddle than a steakhouse that just needs a griddle for a quick sear.

Flat-Top vs. Grooved Griddle Surfaces

The first fork in the road is the cooking surface itself. This choice literally shapes the food you serve.

-

Flat-Top Commercial Griddles: This is the undisputed champion of versatility. A smooth, polished steel surface gives you maximum contact for incredible heat transfer. It's the secret to perfect pancakes, diner-style eggs, chopped cheesesteaks, and that beautiful crust on a smash burger. Its adaptability is its superpower.

-

Grooved Commercial Griddles (Char-Griddles): These are specialists. The raised ridges are designed to mimic a charbroiler, creating those beautiful, dark grill marks on steaks, chicken breasts, and paninis. As a bonus, they let fat and grease drain away from the food. They're perfect for menus that lean heavily into that "just grilled" look and taste.

For many restaurants, a hybrid approach is the smartest play. Pairing a large flat-top griddle with a smaller grooved griddle gives you the flexibility to execute a diverse menu without missing a beat.

Gas vs. Electric Heat Sources

Next up: how are you going to power this thing? Gas and electric commercial griddles each have their die-hard fans, and the best choice comes down to your kitchen's setup, your budget, and how your cooks like to work.

| Heat Source | Pros | Cons |

|---|---|---|

| Gas Griddles | Heats up lightning-fast and offers instant temperature changes, giving chefs that tactile, responsive control they love. | Tends to throw more ambient heat into the kitchen and can sometimes have cooler spots on the surface. |

| Electric Griddles | Delivers incredibly consistent, even heat from edge to edge. Often more energy-efficient in the long run. | Slower to heat up and cool down, which makes quick temperature adjustments a challenge. Requires a high-voltage hookup. |

You'll often see gas griddles in high-volume kitchens where speed and responsiveness are everything. Electric models are killers where absolute consistency is key—think delicate items or operations that need to nail the exact same result every time.

Positioning Your Griddle in the Hot Zone

You've picked the perfect commercial griddle. Now, where do you put it? Poor placement can cripple even the best piece of equipment, creating traffic jams and killing your workflow. The griddle belongs in the heart of the action: the hot zone. This is the core of your cook line, dedicated to all your high-temp cooking.

The rule is simple: Position your highest-volume equipment in the most accessible spot. If 70% of your orders touch the griddle, it needs to be the anchor of your entire line, with all other equipment supporting its function.

Placement starts with the ventilation hood. Your griddle absolutely must live directly under a properly sized Type 1 hood—this is a non-negotiable for safety and health codes. To effectively capture all that grease-laden vapor, the hood needs to extend at least six inches past the griddle on all sides. You also need to leave enough breathing room, typically 18-24 inches on each side, for your cooks to work safely and for easy cleaning.

Think about the griddle's neighbors, too. Placing a fryer right next to it creates a burger-and-fry powerhouse station. Sticking a low-boy refrigerator underneath keeps your proteins right where you need them, saving precious steps. A nearby prep surface ensures a seamless handoff from prep to cook. To dial in that flow, check out our guide on how to choose the right commercial prep table to round out your setup. This is how you turn a simple line of equipment into a high-performance engine that drives your whole operation.

Designing Efficient Stations Around Your Commercial Griddle

So, you've got your commercial griddle in its prime spot on the line. What's next? You need to build its support system. A griddle is only as fast as the stations surrounding it, and the goal here is to create a self-contained, high-speed "griddle cockpit" for your cook.

Think about a pilot's cockpit for a second. Every critical switch, button, and screen is within immediate reach, all organized by how often it's used. This isn't random; it's a deliberate design to slash wasted motion and let the pilot focus on flying. Your griddle station needs that same logic, setting your cook up to succeed during the busiest rush.

Every single thing—from raw ingredients to finished plates—needs a designated home. This simple rule transforms chaotic energy into focused, repeatable output, ticket after ticket.

Creating Strategic Landing Zones

A line cook's hands are always full. They're constantly grabbing, flipping, and plating, so they need clear, designated spots to land ingredients and plates. Without these "landing zones," the area around the griddle quickly becomes a mess, and that chaos grinds everything to a halt.

Your layout has to create a logical path from raw to cooked. Most of the time, this means a simple directional flow:

- The "Raw" Side: This is where ingredients come in. It should have a spot for pre-portioned burger patties or containers of pancake batter. Critically, this space needs to be right next to the immediate-access refrigeration.

- The "Finished" Side: This is your output zone, located on the other side of the griddle. It's where finished dishes get plated. This area must be kept clean, clear, and lead straight to the expo window or pass-through shelf to complete the journey.

This simple left-to-right (or right-to-left) progression is second nature for cooks and is a huge help in preventing cross-contamination.

The Power of Proximity Refrigeration

Having a cook walk even a few extra steps to a reach-in cooler during a dinner rush is a massive waste of time and energy. This is where under-counter refrigeration becomes a total game-changer for any kitchen built around a commercial griddle. Placing a low-boy or chef base refrigerator directly under or next to the griddle is one of the smartest design moves you can make.

An under-counter refrigerator turns a multi-step trip across the kitchen into a single, fluid motion. By stocking it with the top 8-10 high-volume ingredients, you can eliminate up to 80% of a cook's travel time during service.

This unit essentially becomes the griddle's personal pantry. Before service, it gets meticulously stocked with everything needed for the shift's biggest sellers: burger patties, sliced cheeses, bacon, and eggs. This ensures the cook can grab, flip, and plate without ever taking a step. It's an essential piece of any smart commercial kitchen equipment list, creating a true hub of efficiency.

Arranging Your Tools and Seasonings

The final layer of the griddle cockpit is organizing all the small stuff. No cook should ever have to hunt for a spatula, a salt shaker, or their squeeze bottle of oil. Everything needs to be within arm's reach, placed in the same spot every single shift so muscle memory can take over.

Here are a few high-impact ways to make that happen:

- Wall-Mounted Magnetic Strips: This is the perfect home for spatulas, turners, and scrapers. Stick one on the wall right behind the griddle to keep tools visible, clean, and easy to grab.

- Over-Shelving: That shelf above the griddle is prime real estate for salt, pepper, and your signature spice blends. Use standardized, clearly labeled containers so nobody grabs the wrong thing.

- Squeeze Bottle Holsters: Mount holsters or small stainless-steel bins to the side of a prep table for oils, water, and sauces. This keeps greasy bottles from cluttering up the workspace and making a mess.

When you create this highly organized cockpit, you remove the mental tax of searching for items and let the cook focus entirely on what matters: timing and quality. This meticulous attention to station design is how a great restaurant kitchen layout translates directly into faster ticket times and fatter profits.

Real-World Griddle-Focused Kitchen Layouts

Theory is one thing, but seeing it in action is another. Let's step out of the blueprint and into the fire to look at three real-world kitchen layouts where the commercial griddle isn't just another appliance—it's the undisputed star of the show.

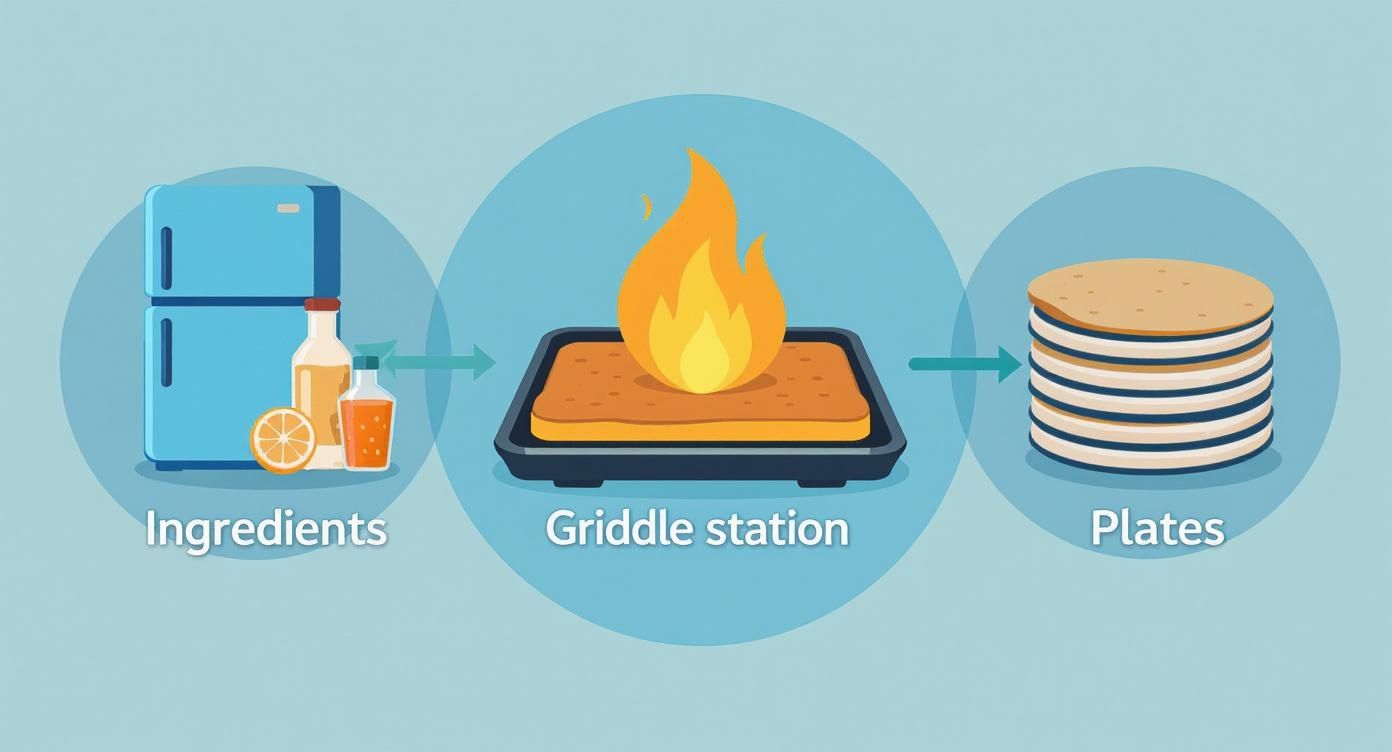

Each setup is built for a totally different kind of business, showing just how much the griddle's role shapes the entire kitchen's flow and function. This infographic breaks down the basic concept of a griddle station, showing how everything quite literally revolves around that hot slab of steel.

You can see the simple, logical path: ingredients come from cold storage, hit the griddle, and then move right over to plating. That's efficiency.

The Classic Diner Assembly Line

Picture a classic American diner. You know the scene: the long counter, the buzz of conversation, and the sizzle coming from that gleaming flat-top griddle. This is the assembly line layout at its absolute best, engineered for one purpose—cranking out huge volumes of simple, delicious food at breakneck speed.

Here, the commercial griddle is the anchor. It’s the centerpiece of a long cook line, often right in view of the customers, which adds a bit of theater to the whole experience. The workflow is built around it from start to finish:

- Prep and Refrigeration: At the beginning of the line, you'll find low-boy refrigerators packed with eggs, bacon, sausage patties, and pancake batter. This setup lets the cook grab and load the griddle without taking a single step away.

- The Griddle Zone: This is where the magic happens. The cook works their way down the length of the griddle, juggling multiple orders at once. Spatulas, oil, and seasonings are all right there on an overhead shelf, always within arm's reach.

- Finishing and Plating: At the very end of the line, right beside the griddle, is the plating area. Toast pops up from a commercial toaster, and plates are lined up, ready to be whisked away through the pass-through window.

This straight-line design is unbelievably efficient for menus where 70-80% of the items come off the griddle. Every station flows directly into the next, creating a smooth, one-way production chain.

The Compact Food Truck Galley

In a food truck, space is everything. Every square inch counts, which is why the galley layout is the undisputed king. This design lines up all the equipment and workstations along two parallel walls, leaving a narrow corridor for the crew to work.

For a griddle-centric truck, this tiny space is planned with military precision. The commercial griddle is usually buddied up with a deep fryer, creating a powerhouse combo that can handle street food staples like burgers and fries. A compact 24-inch or 36-inch griddle is often the workhorse, and its placement dictates where everything else goes.

In a food truck, the commercial griddle isn't just the main cooking appliance; it's the primary heat source and the engine of the entire menu. Its placement determines the location of every other component, from refrigeration to the service window.

Under-counter refrigeration isn't a luxury; it's a necessity. It keeps ingredients chilled and handy without eating up precious floor space. The griddle sits directly under a compact vent hood, and the service window is just a quick pivot away. This means one person can take orders, cook, and serve, all without moving more than a step or two.

The High-Volume Ghost Kitchen Pod

Ghost kitchens are built for pure, unadulterated speed. There are no diners to impress, just delivery apps to please and drivers to dispatch. The layout here is a hyper-efficient assembly line, built around a massive, high-output commercial griddle.

A standard ghost kitchen pod might feature a 48-inch or even a 60-inch griddle as its heart. The workflow is brutally linear and designed for maximum throughput:

- Order Intake: Tickets flash onto a KDS screen mounted right above the griddle station.

- Ingredient Access: The cook grabs pre-portioned ingredients from a dedicated under-counter fridge. Zero wasted motion.

- Griddle Execution: Food hits the massive flat-top, which can handle dozens of orders at the same time.

- Packaging Station: Finished food moves directly from the griddle to an adjacent packaging station to be boxed and bagged.

- Driver Handoff: The completed order is placed on a designated shelf for a driver to grab and go.

This obsession with standardized, speedy layouts isn't new. The post-World War II boom saw a huge surge in standardized kitchen designs across the globe. By the 1970s, over 60% of new restaurants in major markets were using similar layouts to guarantee consistency and efficiency. You can learn more about the evolution of restaurant equipment and see how these foundational ideas developed.

Every one of these modern layouts, from the bustling diner to the lean ghost kitchen, is built on these time-tested principles, simply adapting them to fit their unique business model with the commercial griddle right at the core.

Common Questions About Commercial Griddle Placement

Even the best-laid plans run into questions when it's time to actually place a commercial griddle on the line. Getting these details right from the jump is the difference between a smooth-running kitchen and one that’s plagued by costly, frustrating problems. Let's dig into some of the most common questions we hear from operators.

What Is the Most Common Mistake in Griddle Placement?

Hands down, the biggest mistake we see is failing to give the commercial griddle enough "breathing room." In the rush to cram as much equipment as possible onto the cook line, operators often suffocate their workflow before they even serve the first customer.

Think of it this way: a griddle needs clear landing zones on both sides to function. A cook needs a dedicated spot for raw ingredients on one side and a clean space for finished plates on the other. Jamming a griddle right up against a fryer or a wall forces your cooks into awkward, inefficient motions. This slows everything down, makes cross-contamination a real danger, and drastically increases the risk of burns and spills during a busy service.

As a solid rule of thumb, plan for at least 18 to 24 inches of clear counter space on both the "in" and "out" sides of your griddle. This buffer isn't wasted space—it’s an active part of the workstation that pays for itself in speed and safety.

This space is critical for creating a seamless flow, moving food from the cooler to the cooktop and onto the plate without any hitches. It’s a core principle of good kitchen design.

How Does My Menu Impact Where I Should Place My Commercial Griddle?

Your menu is the ultimate guide for your kitchen layout. The commercial griddle's position on the line should be a direct result of how critical it is to your sales. You need to let your ticket data do the talking here.

For instance, if you're running a smash burger joint and 70% of every ticket has a burger on it, your griddle is the star of the show. It belongs in the most central, easily accessible spot on the hot line, period. Every other piece of equipment, from fryers to prep coolers, should be positioned to support the griddle operator.

On the flip side, if you mainly use your griddle to sear the occasional piece of fish or toast some buns, it doesn't need to hog that prime real estate. In that case, you can place it further down the line. This frees up the central spot for other high-volume equipment. Always design your line to support your best-selling items first.

What Ventilation Is Required for a Commercial Griddle?

Let's be crystal clear: proper ventilation isn't optional. It is an absolute, non-negotiable legal and safety requirement. Commercial griddles pump out a serious amount of heat, smoke, and grease-filled air that has to be captured and removed from the kitchen. Skimping on this is a massive fire hazard, a surefire way to fail your next health inspection, and creates a miserable working environment for your team.

Every commercial griddle must be installed under a Type 1 ventilation hood. These are the heavy-duty hoods specifically built to handle grease and equipped with an integrated fire suppression system.

Here’s what you absolutely need to get right:

- Proper Overhang: The hood must hang over the griddle's cooking surface by at least six inches on all sides. This creates a capture zone that ensures all the smoke and grease go up the flue instead of out into your kitchen.

- Sufficient CFM: The exhaust fan's power is measured in Cubic Feet per Minute (CFM). This rating must be properly calculated based on the griddle's heat output (its BTUs). An undersized fan simply can't keep up, leading to a greasy, smoky kitchen.

- Professional Installation: Don't even think about DIYing this. You need to hire a licensed HVAC professional who specializes in commercial kitchens. They will make sure the system is sized correctly and installed to meet all local fire and health department codes.

Investing in the right ventilation system is just as crucial as the commercial griddle itself. It’s what protects your building, your staff, and your business license.

Ready to build the perfect griddle station for your kitchen? At Griddles.com, we specialize in providing the high-performance, reliable commercial griddles that form the heart of any successful hot line. Explore our collection of gas and electric griddles today and get free shipping on every order.