Mastering Commercial Griddle Ventilation Requirements

When it comes to commercial kitchen codes, ventilation isn't just a suggestion—it's a critical safety mandate for your commercial griddle. Any setup with a commercial griddle absolutely must have a system that pulls heat, smoke, and grease-filled vapors out of the air. This almost always means installing a Type I hood, complete with a powerful exhaust and a matching makeup air system.

These aren't just arbitrary rules. They’re the backbone of kitchen safety, designed to stop fires before they start and keep the air breathable for your crew.

Why Griddle Ventilation Is a Critical Safety System

Think of your commercial griddle like a high-performance engine. It pumps out a ton of heat and byproduct. The ventilation system is its exhaust pipe. Without that pipe, dangerous fumes build up fast, and you’ve got a hazardous situation on your hands. It’s the exact same principle in your kitchen.

Proper ventilation isn't about keeping things comfortable; it's a non-negotiable safety system built to handle the intense environment a busy griddle creates.

This system is essentially your griddle's lungs, constantly breathing out harmful gunk and breathing in fresh air. Its most important job? Protecting your establishment from the number one danger of griddle cooking: grease fires.

Every time you sear a burger or fry up some bacon on the griddle, tiny droplets of grease get launched into the air. Without a strong hood system sucking them up, those grease-laden vapors settle everywhere—on walls, ceilings, and other equipment. This creates a sticky, highly flammable film that's just waiting for a spark.

To get a clearer picture of how these components work together, here’s a quick rundown of the essential parts of a griddle ventilation system.

Essential Ventilation Components for Commercial Griddles

| Component | Key Function for Griddles | Relevant Code (Example) |

|---|---|---|

| Type I Hood | Captures heat, smoke, and grease-laden vapors directly from the griddle. | NFPA 96: Required over cooking equipment that produces grease. |

| Grease Filters | Traps airborne grease particles from griddle cooking before they enter the ductwork, reducing fire risk. | IMC 507.2.8: Must be UL 1046 listed and installed at a specific angle. |

| Exhaust Fan | Pulls the contaminated air from the hood and expels it outside the building. | IMC 506.5: Must be rated for grease-laden vapors and accessible for service. |

| Ductwork | Provides a sealed pathway for the exhausted air to travel from the hood to the fan. | NFPA 96: Must be constructed of 16-gauge steel and welded liquid-tight. |

| Makeup Air Unit | Replaces the air being exhausted, preventing negative pressure and ensuring proper griddle exhaust. | IMC 508.1: Required when exhaust exceeds a certain CFM to ensure balance. |

Each of these parts has a specific job, and if one fails, the entire system's safety and effectiveness are compromised.

Protecting People and Property

Fire prevention is huge, but it's not the only reason for a solid ventilation setup for your griddle. A griddle running full tilt produces a lot of smoke, steam, and even carbon monoxide. An effective system yanks these contaminants out of the air, protecting your staff from respiratory problems and creating a workplace that’s safer and more productive.

This isn’t just a nice-to-have; it's the law. Health and fire codes are incredibly strict, and one failed inspection can lead to hefty fines or even a shutdown order.

A properly functioning ventilation system is the first line of defense against grease fires, which are among the most common and devastating incidents in a kitchen with a commercial griddle. It actively reduces the fuel load, making it a safer place for everyone.

Meeting Modern Standards

The industry's focus on kitchen safety and air quality is only getting stronger. We're seeing huge advancements in ventilation technology, driven by tougher regulations for equipment like griddles. In the United States alone, the commercial kitchen ventilation market is projected to grow at a CAGR of 4.3% between 2025 and 2035. This trend is all about the push for safer, more energy-efficient kitchens.

At the end of the day, understanding why these rules exist is the first step to staying compliant. It all starts with good habits, and a clean system begins with a clean griddle. For more tips on that, check out our guide on how to clean a flat top griddle to keep your primary tool in prime condition.

Decoding Key Ventilation Codes for Your Griddle

Trying to make sense of commercial kitchen ventilation requirements can feel like deciphering a secret code. But for your griddle, it really boils down to two main players: the National Fire Protection Association's NFPA 96 standard and the International Mechanical Code (IMC).

Think of these as the essential blueprints for a safe, functional griddle station. They aren’t just friendly suggestions—they are legally enforced in most places. These rulebooks dictate everything from the type of steel in your ductwork to the placement of your exhaust fan, all with the goal of preventing fires and keeping your staff safe.

The Foundation: NFPA 96

When it comes to fire safety over your commercial griddle, NFPA 96 is the authority. Its main concern for your griddle is simple: dealing with the grease-filled air it produces. Imagine a busy diner flipping hundreds of burgers a day; that griddle creates a ton of airborne grease, which is basically fuel waiting for a spark.

This is exactly why NFPA 96 requires a Type I hood over any commercial griddle. These hoods are built with special grease filters designed to grab those flammable particles right out of the air. If they don't get caught there, they build up in your ducts, creating a serious fire hazard. The code also gets specific about the ductwork, demanding it be made from at least 16-gauge steel and welded liquid-tight to contain a fire if one ever breaks out.

Putting It All Together: The International Mechanical Code

If NFPA 96 is the "what" of fire safety, the International Mechanical Code (IMC) is the "how" of engineering. The IMC lays out the broader mechanical framework for your entire griddle ventilation system. It sets the rules for airflow, construction, and performance.

For instance, the IMC specifies how much air your system needs to pull—measured in Cubic Feet per Minute (CFM)—to effectively capture every bit of smoke, steam, and heat coming off your griddle. It also makes sure your kitchen doesn't turn into a vacuum by requiring a makeup air system to replace the air being exhausted.

At the end of the day, compliance isn't about memorizing codebooks. It's about understanding the core mission: capture grease from the griddle, contain it safely, and get it out of the building without causing other problems.

This focus on safety isn't just a local thing; it’s a global priority. The Asia-Pacific region, for example, made up 20.66% of the commercial kitchen ventilation market in 2023, and developed nations worldwide are adopting similarly tough standards. As the industry expands, so does the push for universal safety. You can dive deeper into these worldwide trends and learn about the commercial kitchen ventilation market's growth.

Ultimately, NFPA 96 and the IMC are a team. One gives you the fire safety rules for your griddle, and the other provides the mechanical playbook to make it happen. Getting a handle on both helps you make smart choices that keep your griddle setup safe, effective, and 100% compliant.

Designing a High-Performance Ventilation System for Your Griddle

Putting together the right ventilation system for your commercial griddle is about way more than just checking a box for the inspector. It’s about building a safe, clean, and efficient cooking environment from the ground up. A great system doesn't just suck out dirty air; it creates a perfectly balanced workspace that protects your crew and your equipment. And it all starts with the griddle itself.

The type of griddle and the cooking you're doing directly impacts how powerful your exhaust system needs to be. Think about it: a small countertop griddle that's only fired up for a few hours a day has totally different needs than a massive 48-inch griddle pumping out burgers and cheesesteaks from open to close. The goal is simple: create a system strong enough to grab every bit of heat, smoke, and grease your griddle produces, even during the craziest dinner rush.

Calculating Your Griddle’s Airflow Needs

The core of any ventilation design is figuring out the right airflow, which we measure in Cubic Feet per Minute (CFM). This number tells you how much air your exhaust fan needs to pull out of the kitchen every minute to keep things safe and clean. Go too low, and you'll end up with a greasy film on every surface—a serious fire hazard. Go too high, and you're just throwing money away on wasted energy.

While a certified pro has to do the final math, you can get a pretty good idea of what you’ll need. Griddles are generally considered "medium-duty" appliances. For a standard wall-mounted hood, a good rule of thumb is about 75 CFM per square foot of the hood's opening. This ensures the fan has enough pull to capture all the smoke and vapor rising off that hot griddle surface. For instance, a hood that's 4 feet wide and 3 feet deep would need around 900 CFM (12 sq ft x 75 CFM).

The whole point of CFM calculation is to hit that sweet spot. You need enough power to clear the air from your griddle effectively without making your kitchen feel like a wind tunnel. Getting this balance right is everything for both safety and your utility bills.

The Importance of Makeup Air

An exhaust fan is only half the story. All that air getting pulled out of the kitchen has to be replaced. If it's not, you're creating a vacuum. That's where a makeup air unit (MUA) comes in. It pulls fresh air from outside—often heating or cooling it first—and pumps it back into the kitchen.

Without enough makeup air, you create what's known as negative pressure, which can cause some real headaches for your griddle station:

- Weak Exhaust: The exhaust fan has to fight against the vacuum, making it much less effective at capturing grease and smoke from your griddle.

- Dangerous Back-Drafting: This is a big one. Negative pressure can actually suck dangerous gases like carbon monoxide back down the flues of other gas appliances in the kitchen.

- Struggling with Doors: Ever tried to open a door that feels like it’s being held shut by an invisible force? That’s negative pressure.

A well-designed system will typically replace about 80-90% of the air being exhausted. This creates just a slight negative pressure, which is actually a good thing—it helps keep cooking smells contained in the kitchen instead of wafting out into your dining room. The type of griddle you have can also affect these numbers. If you want to dive deeper into fuel types, our article on natural gas versus propane griddles has some great info. At the end of the day, a great ventilation system is a balancing act between what goes out and what comes in, turning complex codes into a safer, more comfortable kitchen.

Choosing the Right Ventilation Hood for Your Griddle

Think of your ventilation hood as the griddle's first line of defense. When you're running a commercial griddle, it's kicking off intense heat and grease, and the hood is what stands between a clean kitchen and a hazardous one. Picking the right hood isn't just about passing an inspection; it's about keeping your staff safe and your griddle station running smoothly.

For any griddle that cooks with grease—and a commercial griddle definitely qualifies—the choice is non-negotiable: you absolutely need a Type I hood. A Type II hood just can't cut it. Those are designed for steam and heat only, like what comes off a pasta station.

A Type I hood is engineered specifically to trap grease-laden vapors, which is a massive fire hazard. The built-in baffle filters work like a net, catching flammable grease particles before they have a chance to build up in your ductwork. It's a critical safety feature for any griddle.

Wall-Mounted vs. Island Hoods for Griddles

Okay, so you know you need a Type I hood. The next step is figuring out which style fits your kitchen layout. Your griddle's location will point you to one of two common options: a wall-mounted canopy or an island hood.

- Wall-Mounted Canopy Hoods: These are the workhorses of the industry. If your griddle is pushed up against a wall, this is your most efficient option. It mounts right on the wall and hangs over the cooking surface, using the wall itself to help funnel smoke and grease straight up.

- Island (or Center Canopy) Hoods: Got your griddle in the middle of the kitchen as part of a cooking island? You'll need an island hood. These are much bigger units that hang from the ceiling and are designed to pull air from all sides, since there are no walls to guide the flow.

A wall-mounted setup almost always performs better for a griddle because the wall acts like a natural backsplash, directing all that hot, greasy air where it needs to go. Island hoods have a tougher job—they have to capture fumes from a full 360-degree area, which often means they need a more powerful fan (higher CFM) to get the job done right.

The rule of thumb here is simple: your hood has to match your griddle’s location. Trying to use the wrong style will wreck your capture efficiency, leaving you with a greasy kitchen and a failed inspection report. The entire goal is to create a negative pressure zone that sucks every bit of griddle smoke up and out.

To help you decide, here’s a quick breakdown of the common hood styles and where they work best for a griddle.

How to Choose the Right Type I Hood for Your Griddle

| Hood Style | Ideal for Griddle Location | Key Advantages | Potential Drawbacks |

|---|---|---|---|

| Wall-Mounted Canopy | Griddle placed against a solid wall. | Most efficient capture; often requires lower CFM; more affordable. | Limited to perimeter layouts; less flexible if you redesign the kitchen. |

| Island Canopy | Griddle located in a central island or peninsula. | Provides ventilation for open-concept cook lines. | Less efficient capture; requires higher CFM; more expensive to install. |

| Backshelf Hood | Low-profile griddles or countertop units against a wall. | Space-saving design; ideal for tight kitchens with low ceilings. | Limited capture area; not suitable for heavy-duty, high-volume griddles. |

| Eyebrow Hood | Directly mounted on equipment like conveyor ovens (less common for griddles). | Highly targeted ventilation; very efficient for specific appliances. | Inflexible; only works for the equipment it's designed for. |

Ultimately, the best choice locks into your kitchen's unique design and the intensity of your griddle station.

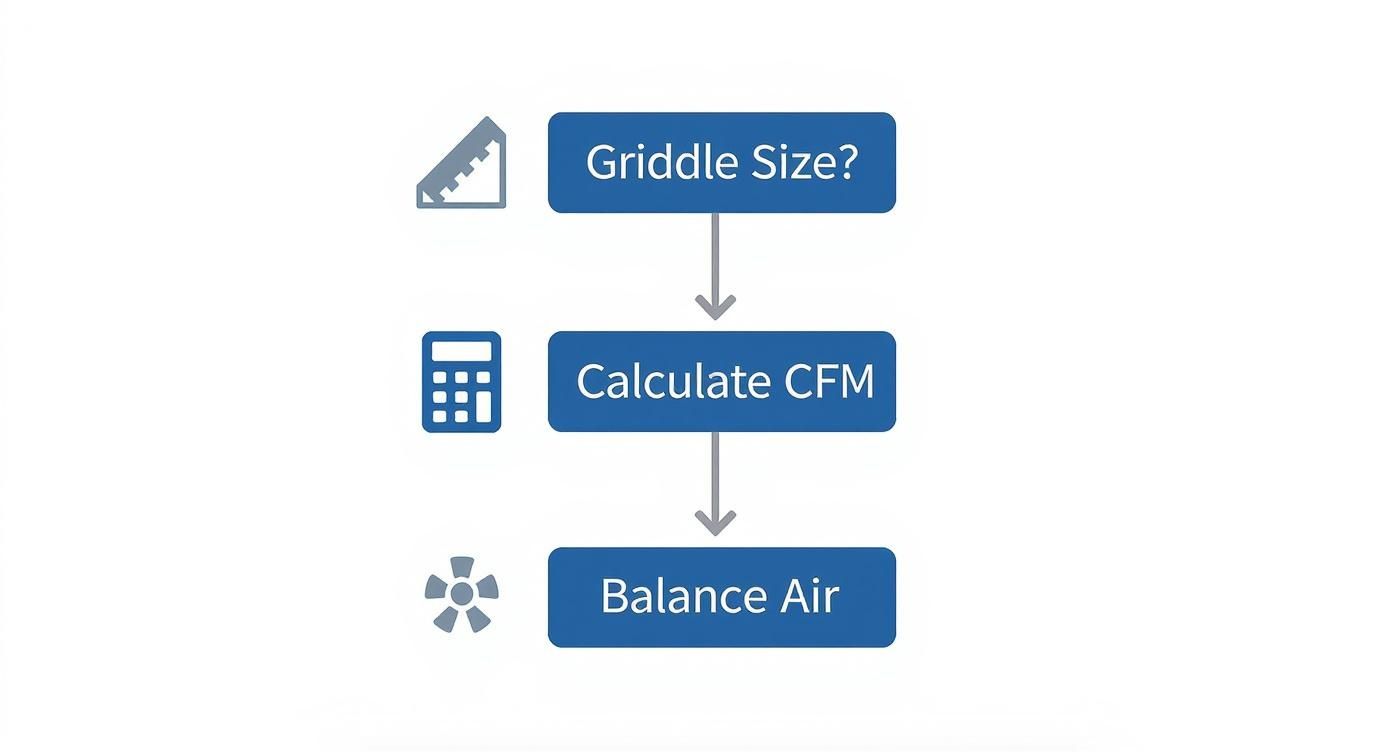

This decision-making process is a lot easier to see visually.

As the infographic shows, a solid ventilation plan starts with the size of your griddle. That measurement dictates your airflow (CFM) calculations and drives the critical need for balanced makeup air. The final commercial kitchen ventilation requirements depend on both the griddle itself and where you put it. A hood that fits your workflow is the key to a safer, cleaner, and more compliant griddle station.

Installation and Maintenance Best Practices for Griddle Ventilation

You can pick the perfect ventilation hood for your griddle and map out a brilliant system, but it's all for nothing if the installation is botched or you let maintenance slide. Even the most high-end equipment is doomed to fail without a professional setup and regular care. It's like buying a race car; if the engine isn't installed right or you never bother to change the oil, a breakdown is just a matter of time.

Getting the setup and upkeep right is what brings your system to life. It’s how you’ll fly through inspections, get more years out of your equipment, and shield your griddle-focused kitchen from the constant threat of a grease fire.

Avoiding Common Installation Pitfalls

When it comes to commercial kitchen ventilation requirements, professional installation isn't just a good idea—it's non-negotiable. Trying to DIY it or hiring some uncertified handyman for your griddle's hood is just asking for trouble. We're talking failed inspections, a voided insurance policy, and major safety hazards.

Certified pros know how to sidestep the critical mistakes that always trip up amateurs. Some of the most common blunders include:

- Incorrect Ductwork Sizing: Ducts that are too small force the exhaust fan to work way too hard. This leads to burnout and means the hood won't capture smoke and grease effectively from the griddle.

- Improper Fan Placement: NFPA codes have strict rules about how far exhaust fans and makeup air intakes need to be from the roofline. Getting this wrong can lead to cross-contamination or create a serious fire risk.

- Poorly Sealed Ducts: Any little gap or leak is an escape route for grease. It builds up in your ceiling or on the roof, creating a hidden and highly flammable problem.

Hiring a licensed professional who lives and breathes NFPA 96 ensures every single part is installed correctly, from the hood's overhang above your griddle to the grease trap on the roof.

"A certified installation isn't an expense; it's an investment in safety and compliance. It's the only way to guarantee that your ventilation system will function as a life-safety device, which is its primary purpose."

Creating a Proactive Maintenance Schedule

Once your system is installed and humming along, the real work begins: proactive maintenance. Grease is the relentless enemy of any griddle kitchen, and a solid cleaning schedule is your only defense. Letting it accumulate is like stacking kindling in a fireplace—sooner or later, you'll get a spark.

A good maintenance plan is about more than just keeping things clean; it’s about safety and efficiency. This isn't just swapping out filters. It’s a top-to-bottom approach that keeps your griddle station safe.

Here’s a realistic maintenance schedule you can stick to:

- Grease Filters (Daily/Weekly): Clean those hood filters! If you're running a high-volume griddle station, this might be a daily job. At the absolute minimum, they need to be cleaned weekly to keep air flowing and trap grease.

- Hood Canopy (Weekly): Wipe down the inside and outside of the hood. This catches any grease that managed to get past the filters from the griddle.

- Exhaust Fan (Quarterly to Semi-Annually): The fan blades and housing need a professional cleaning every three to six months, depending on how much griddle cooking you do. This keeps the fan efficient and balanced.

- Full Ductwork (Semi-Annually to Annually): NFPA 96 requires the entire duct system to be professionally cleaned down to the bare metal. For a kitchen with moderate griddle volume, plan on this service every six months.

When you follow a schedule like this, maintenance stops being a chore and becomes one of your most important safety procedures—one that protects your griddle, your people, and your business.

Common Questions About Griddle Ventilation

Even after you've nailed down the big picture, a few specific questions always pop up when it comes to griddle ventilation. We hear them all the time. Let's run through the most common ones and get you some straight, real-world answers.

Does My Small Countertop Electric Griddle Need A Type I Hood?

Yes. Almost without exception, it absolutely does. This is probably the number one point of confusion we see around commercial kitchen ventilation requirements for griddles.

Here's the key: the need for a Type I hood isn't about whether the griddle is gas or electric, or big or small. It's about what you're cooking on it. If you're cooking anything that produces grease-laden vapors—think burgers, bacon, sausage, anything of the sort—you're creating a serious fire hazard. Fire codes are written specifically to deal with that grease.

So, even if your electric griddle is tiny, the moment you throw down some bacon, you need that Type I hood to safely capture and exhaust the grease. Always double-check with your local fire marshal, but consider this the golden rule: if it makes grease in a commercial kitchen, it needs a Type I hood.

How Often Should My Griddle Ventilation System Be Cleaned?

How often you need to clean your system comes down to one thing: how much you use your griddle. The NFPA 96 standard lays out the schedule pretty clearly, and you don't want to mess with it.

- High-Volume Operations: If your griddles are firing 24/7, like in a busy diner, you need a professional inspection and cleaning quarterly.

- Moderate-Volume Operations: This covers most typical restaurants with a griddle station. Plan on a professional cleaning every six months (semi-annually).

- Low-Volume Operations: For places with occasional griddle use—think church kitchens or seasonal spots—an annual cleaning is usually sufficient.

And don't forget to document everything. Keep a log of every cleaning and inspection. That log is your proof of compliance for the fire inspector and your insurance company.

A clean ventilation system is a safe one. Sticking to a documented cleaning schedule isn’t just about checking a box; it’s the single most important thing you can do to prevent a catastrophic grease fire originating from your griddle.

What Is Makeup Air And Why Is It Essential For My Griddle?

Think of it this way: your exhaust hood is basically a giant vacuum cleaner, sucking massive amounts of air out of your kitchen every minute. Makeup air is the fresh, clean air that's intentionally brought back into the kitchen to replace what was removed.

Without it, you create negative air pressure. Your kitchen literally becomes a vacuum-sealed room. This causes a ton of problems. Your hood won't be able to properly grab the smoke and grease from your griddle. Worse, it can cause dangerous back-drafting, pulling carbon monoxide from other gas appliances back into the room. It can even make opening the kitchen doors a workout.

A proper makeup air unit (MUA) keeps the air pressure balanced, ensuring your entire ventilation system works like it's supposed to and your kitchen is safe for your crew.

Can I Install My Own Griddle Ventilation To Save Money?

In a word: no. Do not even think about it. This isn't a simple DIY project; it's a critical life-safety system. Commercial griddle ventilation is heavily regulated by NFPA 96 and your local fire and building codes for a reason—improper installation is incredibly dangerous.

A DIY job is a guaranteed way to fail your inspections, void your business insurance, and put your entire operation at risk of fire.

More importantly, you'd be creating a massive fire hazard. You absolutely must hire a licensed and certified professional who does this for a living. They're the only ones who can ensure your system is installed correctly, safely, and legally. It’s a non-negotiable part of setting up a commercial griddle station.

Ready to build out a high-performance griddle line that can handle any rush? At Griddles.com, we specialize in providing the durable, reliable flat-top griddles that form the heart of any successful kitchen. Explore our full catalog of commercial griddles and cooking equipment.