Commercial Griddle Maintenance: Master the Art of a Longer Griddle Life

If there's one mistake that consistently hurts a commercial kitchen, it's failing to properly maintain the griddle. Think about it like running a high-performance car engine without ever touching the oil—you wouldn't, right? Performance would tank, costs would spiral, and a total breakdown would be just around the corner.

That's exactly what happens to your griddle. Proper commercial griddle maintenance isn't some fancy add-on; it's a core tool for keeping your business profitable.

The True Cost of Skipping Griddle Maintenance

Look at your griddle as a critical, and expensive, part of your kitchen. Every single time you neglect its cleaning and seasoning, you are literally letting money slip away. This isn't just about the cost of a new griddle. It kicks off a domino effect that hits your kitchen's speed, the quality of your food, and your overall bottom line.

The financial damage from ignoring maintenance really breaks down into two buckets: the costs you see, and the costs you don't. Both can seriously hurt your operation.

Direct Financial Drains

These are the obvious expenses, the ones that show up loud and clear on your invoices and P&L statements. They’re the tangible costs that eat away at your profit margins right now. Skipping commercial griddle maintenance leads straight to these problems:

- Higher Energy Bills: A griddle covered in carbon buildup has to work much harder to heat up and maintain its temperature. This inefficiency directly translates to higher gas or electric bills every single month.

- Paying More for Cleaning Supplies: When you let grease and carbon build up, you end up needing more aggressive, expensive chemicals to get the surface clean, increasing your supply costs.

- Killing Your Equipment: That thick, caked-on residue makes your griddle's heating elements work overtime. This constant strain causes more frequent breakdowns, expensive service calls, and ultimately, a much shorter life for a vital piece of your kitchen equipment.

Indirect and Hidden Costs

Just as damaging are the hidden costs—the sneaky expenses that quietly chip away at your reputation and mess with your kitchen's rhythm. They're tougher to put a number on, but their impact can be devastating in the long run.

For any restaurant, keeping operational costs low while ensuring food is safe and delicious is the name of the game. A clean griddle keeps your food tasting pure and cooking efficiently, preventing the gunk that can ruin flavors and slow down service.

When a griddle surface degrades, major issues follow. Food cooked on a dirty surface can pick up burnt, off-flavors. It also cooks slower and unevenly because the surface can't transfer heat as well, which means longer ticket times during a chaotic dinner rush. That kind of inconsistency is what makes loyal customers think twice about coming back.

These hidden costs show why managing your griddle isn't just about saving a few bucks on supplies. It’s about protecting the food you serve and the efficiency of your entire kitchen.

How Griddle Seasoning and Cleaning Actually Works

To really get why commercial griddle maintenance is a game-changer, you have to understand what’s happening on that flat-top surface. Think of your griddle as a tiny, hot battlefield. Every time you throw down a burger or pancake, it's war between your clean surface and a triple threat: high heat, food residue, and oxygen.

This constant fight breaks down your griddle's seasoning, kills the flavor of your food, and creates nasty carbon buildup you don't want anywhere near your customers. Regular cleaning and re-seasoning is your griddle’s best defense—it’s the process of removing the bad stuff to keep your surface non-stick and ready for action.

The Villains of the Griddle Surface

Three main culprits are hell-bent on turning your smooth, seasoned griddle into a dark, sticky mess. They each have a different attack plan, but they all lead to the same bad ending: gross food and money down the drain.

-

Stray Food Particles: You know all those little bits of food and char that get left behind? They don't just disappear. They get scorched, turning into carbon deposits that make your griddle sticky and your food taste burnt.

-

Sugar and Acidic Foods: Ingredients like marinades, sauces, and even tomatoes can strip away the griddle's seasoning. This chemical reaction breaks down the non-stick polymer layer, leaving the raw metal exposed and prone to sticking.

-

Oxidation: Just being exposed to the air and moisture causes oxidation, or rust. This is especially true if the seasoning is compromised. A rusty griddle is unusable and can ruin food. The process goes into overdrive when the surface is not properly oiled.

These enemies don’t work alone; they team up to speed up the griddle's death spiral. More carbon bits mean more sticking, and a compromised seasoning makes the surface even weaker against future damage.

How Cleaning and Seasoning Fights Back

A good maintenance routine is like a restoration project for your griddle. Its only job is to physically remove the gunk before it can build up and ruin everything. The process is simple, but it’s incredibly effective.

The whole idea is just to separate the bad stuff from the good surface. By scraping away food residue and carbon, and then applying a new layer of oil to create a non-stick seasoning, you stop the chain reaction that ruins your griddle. It’s that straightforward.

This is way more than just a quick wipe-down. Proper cleaning removes particles that cause sticking and flavor transfer. Re-seasoning creates a durable, slick surface through a process called polymerization. While we're talking about griddles, understanding the general principles of filtration and equipment protection for other equipment really highlights how crucial maintenance is for quality and machine lifespan.

More and more kitchens are catching on. The demand for high-quality commercial griddles is on the rise, largely because operators are demanding equipment that's easier to maintain and built to last. For anyone buying equipment from us here at Griddles.com, choosing a griddle with a thick, durable plate and simple controls means real, measurable savings in your pocket. You can learn more about equipment trends in the full commercial deep fryer report.

Comparing Commercial Griddle Cleaning Tools and Techniques

Choosing the right commercial griddle cleaning tools is a lot like picking a new vehicle. You wouldn't buy a massive pickup truck for a short city commute, and you wouldn't rely on a compact car to haul heavy equipment. It's all about matching the tool to the job. For your kitchen, the goal is finding that sweet spot between upfront cost, day-to-day labor, and sheer cleaning power.

The reality is, not all cleaning methods are created equal. They run the gamut from simple, hands-on scrapers to specialized cleaning systems that do the heavy lifting for you. Getting a handle on the pros, cons, and best-fit scenarios for each will help you make a smart investment—one that pays you back in labor savings and consistently fantastic food.

Let's dive into the three main types of commercial griddle cleaning methods you'll find out in the wild.

Manual Scrapers and Bricks

This is the most old-school, bare-bones approach you can take. It’s exactly what it sounds like: using a metal scraper throughout the day to remove food bits, and a griddle brick or screen at the end of the day to scrub away tougher buildup.

It's about as simple as it gets, requiring just a few basic tools. But that simplicity comes with some serious trade-offs.

- Pros: It has the lowest initial investment, hands down. For kitchens on a shoestring budget or with lighter griddle usage, it’s a way to get the job done.

- Cons: This method is a time sink. It’s slow, labor-intensive, and can scratch or damage the griddle surface if not done correctly. The cleaning quality can also be hit-or-miss, often leaving behind fine layers of carbon.

- Best For: Small-scale operations, food carts, or kitchens that don't rely heavily on their commercial griddle and are willing to trade convenience for a lower upfront cost.

Liquid Griddle Cleaners

Taking a big leap forward, liquid cleaners are specially formulated to break down baked-on grease and carbon when applied to a hot griddle. You pour the solution on, let it bubble and lift the residue, and then scrape or squeegee it all into the grease trap.

These cleaners hit a fantastic middle ground. You get far superior cleaning power compared to dry scraping, but without the high price tag of a fully automated system. They're a go-to choice for countless independent restaurants. In fact, our guide on commercial propane fryers often points to models from brands that also offer excellent commercial griddles.

A liquid cleaner turns a tough, multi-step chore into a streamlined process. It centralizes the cleaning task, dramatically reducing the physical effort needed and improving the consistency of your griddle's surface.

This approach brings real efficiency and powerful cleaning into your kitchen. The chemical action does the heavy lifting, making the entire process quicker and, most importantly, more effective for your staff.

All-in-One Cleaning Systems

This is the top of the line for commercial griddle cleaning. These systems typically include a pre-portioned liquid cleaner, a specialized holder, and a heavy-duty scouring pad. The entire process is designed to be fast, safe, and efficient.

The whole process is incredibly quick, safe, and efficient, often taking just a few minutes. Because the systems are designed with long handles and specific tools, your team has less exposure to the hot surface, making it the safest option by a country mile.

- Pros: Unbeatable speed, safety, and convenience. It makes cleaning so easy that your staff will actually do it properly more often, leading to the longest possible griddle life and top-tier food quality.

- Cons: This is the most expensive option in terms of ongoing supply costs, as you're buying a complete system of products.

- Best For: High-volume kitchens like quick-service restaurants, bustling diners, and any spot where the commercial griddle is a menu cornerstone. In these settings, the ROI from labor savings and consistent results quickly makes up for the supply cost.

To make the choice a bit clearer, we've put together a simple table to see how these three systems compare side-by-side.

Comparison of Commercial Griddle Cleaning Methods

This table breaks down the key features of the three primary commercial griddle cleaning methods to help you decide which one is the right fit for your kitchen's unique needs.

| Cleaning Method | Initial Cost | Labor Intensity | Surface Preservation | Best For |

|---|---|---|---|---|

| Manual Scrapers/Bricks | Very Low | High | Moderate | Low-volume, budget-focused kitchens |

| Liquid Cleaners | Low | Medium | Good | Mid-to-high volume independent restaurants |

| All-in-One Systems | Low | Very Low | Excellent | High-volume QSRs and busy diners |

At the end of the day, the best system is the one your team will actually use, and use consistently. A top-tier system is worthless if it's too complicated for your staff, just as a simple scraper is a nightmare for a kitchen pushing out hundreds of burgers a day. Take a hard look at your volume, budget, and labor to pick the cleaning partner that will best protect your griddle, your food, and your bottom line.

Calculating the ROI of Your Griddle Maintenance Routine

Thinking about a commercial griddle cleaning routine as just another chore is missing the point. It’s a money-making strategy, plain and simple. The real magic happens when you stop thinking about the effort and start looking at the cold, hard numbers. Running the ROI (return on investment) shows you exactly how this one daily task can become one of the most profitable activities in your entire kitchen.

When you frame it as a business decision, you see how quickly the time spent disappears against the massive, ongoing savings. The math is surprisingly simple, and it shines a spotlight on how much cash you’re burning by working on a dirty, inefficient griddle. Let's break down where the savings come from.

The Core ROI Calculation

At its heart, the ROI on a good griddle maintenance routine comes down to tracking savings in three key areas: energy, labor, and equipment lifespan. These are the real-world financial wins you'll see right away.

Let's run the numbers for a small, busy diner to see how this plays out.

- Initial Investment: The diner invests in an all-in-one cleaning system with a yearly supply cost of $500.

- Energy Consumption (Before): With a dirty griddle, their energy costs for that unit are $200 per month, or $2,400 a year. Ouch.

- Energy Consumption (After): With daily cleaning, the griddle is more efficient and heats evenly. They cut energy use by 15%. The new annual cost is $2,040.

That one change creates an instant annual savings of $360 on energy alone. The cleaning system is already mostly paid for by this one factor, proving a ridiculously fast return.

But the savings don’t stop there. You also have to factor in the lower costs for labor and the extended life of the griddle, which makes the payback period even shorter.

Factoring in Labor and Equipment Costs

Nobody enjoys wrestling with a caked-on, greasy griddle. It's a tough, time-consuming job. A good cleaning system makes the process quicker and safer, freeing up your team to do more valuable things—like cooking.

Let's go back to our diner example:

- Labor Savings: A manual deep clean takes a good 30 minutes. The new system gets it done in 10. That’s 20 minutes of labor saved daily. At an average wage of $15/hour, that adds up to another $1,825 in labor savings per year.

- Equipment Savings: The diner used to replace their $3,000 commercial griddle every 5 years. By maintaining it properly, they can extend its life to 8 years, saving an average of $225 annually on equipment replacement.

Add it all up, and the total annual savings hit $2,410 ($360 from energy + $1,825 from labor + $225 from equipment), all for a $500 investment in supplies. The ROI is undeniable. This isn't just a hypothetical, either—operators everywhere are focusing more on maintenance. In fact, the market for commercial deep fryer parts is a great indicator of this trend, expected to explode from USD 295.0 million in 2025 to USD 916.3 million by 2035. That massive growth signals a clear industry trend toward making existing equipment last longer and run smarter. You can discover more about this market expansion and what's driving it.

The final piece of the ROI puzzle isn't something you can easily put on a spreadsheet, but it's just as crucial: food quality. A consistently clean griddle means a consistently better product. We're talking better sear, no flavor transfer, and food that makes customers happy and keeps them coming back. That boost in quality and loyalty protects your most important asset of all—your revenue.

A Step-by-Step Daily Griddle Maintenance Routine

Having the right gear is only half the battle. Making cleaning and seasoning an unbreakable, end-of-day habit is where you really start to see the savings and the boost in food quality. This isn't just another cleanup task to rush through—it’s a core process that protects your griddle, your equipment, and ultimately, the food you serve.

When you create a clear, step-by-step process, you eliminate the guesswork. Every member of your team can perform the task correctly and safely. Think of it less like a chore and more like a closing ritual that tees up the next day for success. Making maintenance a non-negotiable part of your workflow turns an occasional job into a serious operational advantage.

Preparing for a Safe Cleaning Cycle

Let's be clear: we're dealing with a hot surface, so safety is everything. Before anyone starts, the area needs to be clear of clutter and the right personal protective equipment (PPE) must be on. That means heat-resistant gloves and an apron, no exceptions. The sweet spot for cleaning is when the griddle is still hot, usually around 300-350°F (149-177°C).

Don't rush this part. Skipping the safety gear or trying to clean while the kitchen is still chaotic is asking for trouble. Make sure your cleaning tools are ready and the grease trap is not overflowing to prevent any dangerous spills.

The End-of-Day Cleaning Process

Follow these steps at the close of every business day. This simple routine will keep your griddle in prime condition and ready for the next service. Consistency here is key, and it's just one piece of the puzzle. For a bigger picture on keeping your kitchen running smoothly, check out our guide to commercial kitchen equipment maintenance.

- Scrape Down the Griddle: While the griddle is still hot, use a good scraper to remove all loose food debris and grease. Push everything into the grease trap.

- Apply Griddle Cleaner: Pour your liquid cleaner or use your all-in-one system on the hot surface. It will start to bubble and steam, lifting the baked-on carbon and grime.

- Scrub the Surface: Use a griddle pad or brick to scrub the entire surface thoroughly. Work in small sections to ensure you've loosened all the residue.

- Squeegee and Rinse: Use a squeegee to pull all the dirty liquid and debris into the grease trap. Follow up with a small amount of water (or club soda) and squeegee again until the surface is clean and dry. Never use soap.

- Season the Griddle: Once the griddle is clean and dry, pour a small amount of cooking oil on the surface. Use a clean cloth to spread a thin, even layer of oil over the entire griddle. Let it smoke for a few minutes until it polymerizes, then turn the griddle off.

"A daily cleaning routine should be as automatic as wiping down the counters. It's a fundamental task that has a direct, measurable impact on food quality and operational costs. Make it a non-negotiable part of your closing procedure."

By building these five steps into your daily closing checklist, you guarantee that every shift begins with a clean, high-performing griddle. This routine doesn't just extend the life of your griddle; it ensures every customer gets the consistent, high-quality food they expect.

Choosing the Right Commercial Griddle for Your Kitchen

Picking the right commercial griddle is more than just a technical choice—it's a business decision. The right setup can improve your workflow, boost your profits, and keep your food tasting fantastic. It's all about finding the model that fits your kitchen like a glove.

To get there, you need to ask a few honest questions about how your kitchen really runs. There’s no one-size-fits-all answer, but by looking closely at your daily grind, the best option will become obvious.

Assess Your Kitchen's Cooking Volume

First up, what’s your daily output really look like? Are you a high-volume spot churning out hundreds of burgers every day, or a smaller diner where the griddle is more of a supporting actor? Your cooking volume is the biggest piece of the puzzle.

- Low Volume (e.g., small cafes, food trucks): If your griddle isn't running nonstop, a simple countertop model will probably do the trick. It’s cheaper to start with and powerful enough for smaller batches.

- Medium to High Volume (e.g., busy diners, independent restaurants): This is where standard-duty floor models really shine. They offer a larger cooking area and more power without the massive footprint of a heavy-duty unit. For most independent spots, this is the smartest investment you can make.

- Very High Volume (e.g., QSR chains, large institutions): When your griddles are going from open to close, a heavy-duty commercial griddle with a thick plate is the only way to go. The upfront cost is higher, but the heat retention and durability make it the most profitable choice in the long run.

Evaluate Budget and Menu Needs

Next, let's talk money and menu. You have to consider the initial cost of the equipment plus the ongoing energy expense. Just as important, what will you be cooking? A thick steel plate is great for burgers and steaks, while a chrome top is perfect for delicate items like eggs and pancakes.

The most effective commercial griddle is the one that matches your kitchen's menu and output. Prioritize a model that fits your space and labor capacity to ensure consistent execution.

For example, a thermostatically controlled griddle costs more, but it gives you precise temperature control for consistent results. If you're looking for general advice on purchasing decisions, this essential kitchen appliance buying guide offers some great principles.

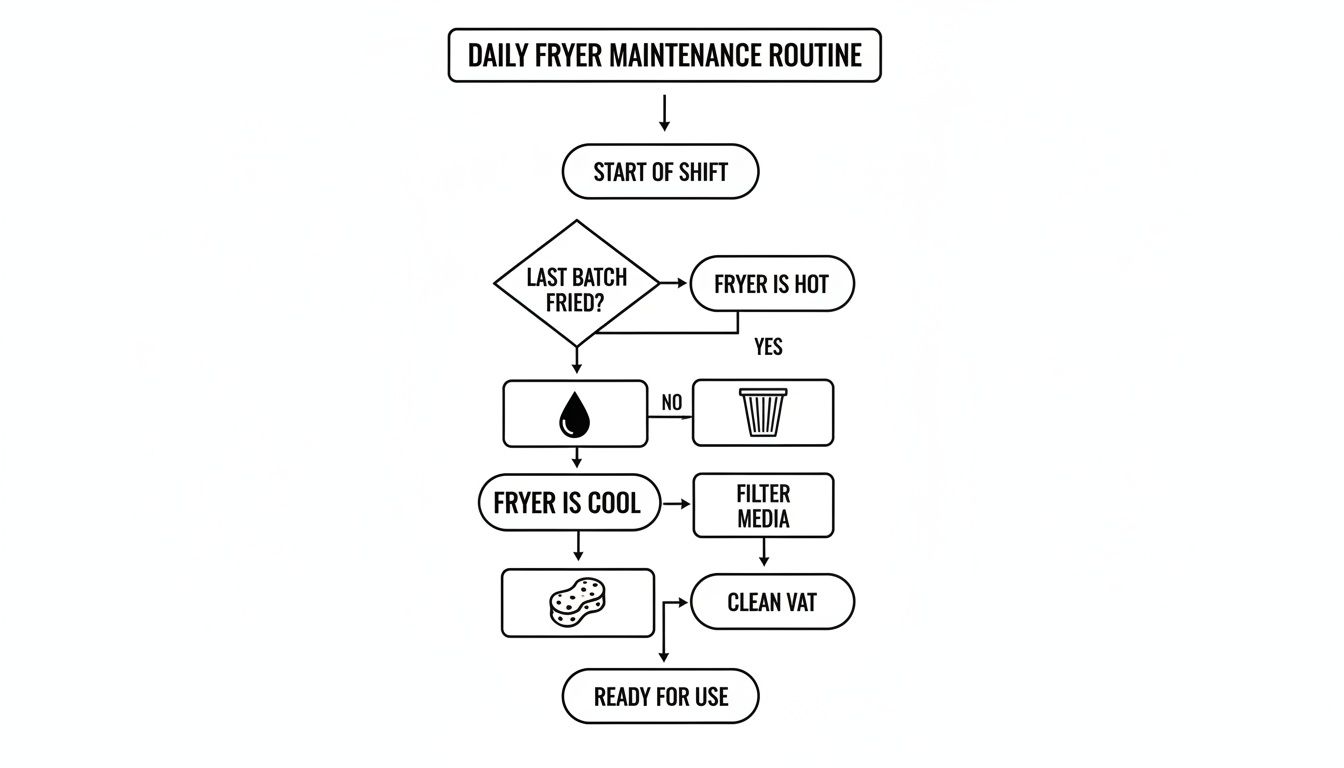

This flowchart breaks down the simple, repeatable steps for a daily routine that protects your griddle and your profits.

This visual shows that the basic process—scrape, clean, season—is the same no matter what. The right gear just makes it all faster, safer, and a lot more effective.

The market backs this up. Quick-service and full-service restaurants drive about 42.76% of the demand for cooking equipment. With tougher rules on kitchen maintenance, good cleaning practices are quickly becoming a requirement, not a choice. By answering these key questions, you can confidently pick the commercial griddle that will give you the best return on your investment.

Frequently Asked Questions About Commercial Griddles

Even with the best griddle in place, questions about commercial griddle maintenance are going to pop up during a chaotic dinner rush. Having quick, solid answers keeps your team working confidently and your food quality high. Here are a few of the most common things we hear from kitchen operators about keeping their griddle in top shape.

How Often Should I Clean My Griddle?

For the best results, you need to scrape the griddle continuously throughout the day and perform a full clean and re-season at least once a day, usually when you're closing up. If you're a high-volume spot cooking a ton of items with sugary marinades, you'll probably see huge benefits from cleaning more often.

Making daily cleaning a non-negotiable part of your routine is the single best thing you can do to extend the life of your griddle.

Don't think of daily cleaning as another chore. It's a direct investment in your bottom line. Those few minutes at closing will literally pay you back with thousands of dollars in labor and energy savings over a year.

What's the Best Oil for Seasoning a Commercial Griddle?

Pretty much any high-smoke-point cooking oil will work. Standard vegetable oil, canola oil, or specialized griddle oils are all great choices. The key is to apply a very thin layer and heat it until it stops smoking. This creates a hard, non-stick surface. Avoid butter or oils with low smoke points as they will burn and become sticky.

When Is It Time to Replace the Griddle?

Proper maintenance works wonders, but no griddle lasts forever. Eventually, it may wear down, and you have to know when to call it quits. It's time for a new one when you see these unmistakable signs:

- Warped Surface: The griddle surface is no longer flat, causing oil to pool and food to cook unevenly.

- Deep Pitting or Cracks: The surface has significant damage that can't be fixed by cleaning and seasoning.

- Inconsistent Heat: The griddle has hot and cold spots that can't be resolved by maintenance, indicating failing heating elements.

- Constant Repairs: You're spending more on service calls and parts than the griddle is worth.

These are all red flags that the griddle is at the end of its life. If you keep using it, you're just going to serve inconsistent food and hurt your reputation.

Ready to stop struggling with a worn-out griddle and start serving food that keeps customers coming back? The experts at Griddles.com can help you find the perfect commercial griddle for your kitchen. Explore our selection of high-performance commercial deep fryers today!