Reducing Food Waste in Restaurants One Commercial Griddle at a Time

Let's be honest, when you're hunting down food waste in your kitchen, the commercial griddle is probably the last place you look. We're trained to focus on plate scrapings and walk-in inventory, but that gleaming flat top can be a silent profit killer.

Every burnt pancake, mangled fish fillet, or overcooked burger that gets tossed is a direct hit to your food cost. This isn't just about big mistakes; it's a slow, steady drain caused by inefficient commercial griddle use—from wonky temperatures to sloppy technique. It's time to turn that hot surface from a hidden waste generator into one of your best cost-control tools.

Your Commercial Griddle Is a Secret Food Waste Hotspot

It’s easy to overlook, but think about it: your commercial griddle is a workhorse. And if it's not managed with precision, it's a major source of loss. Every single item that comes off that flat top wrong—burnt, undercooked, or torn—is money straight into the bin.

Often, the problem starts with something as simple as temperature. An improperly calibrated commercial griddle with mystery hot spots is a recipe for disaster. You get a burger patty that's charred on one side and raw on the other, forcing a re-fire or a trip to the trash. That doesn't just waste the protein; it wastes the cook's time, the gas, and the kitchen's momentum.

The True Cost of Commercial Griddle Inefficiency

This waste adds up faster than you'd think. The restaurant industry is tough enough without throwing away perfectly good product. A single restaurant can generate up to 75,000 pounds of waste a year, with studies showing 4% to 10% of purchased food is lost before it ever gets to a customer, often due to prep errors on equipment like the commercial griddle.

This is exactly why mastering your commercial griddle is a smart financial move. The difference between a profitable shift and a losing one can come down to knowing your griddle's heat zones or making sure it's seasoned correctly to prevent sticking.

A well-managed commercial griddle doesn't just cook food; it protects your inventory. Every item that comes off that flat top perfectly cooked is a victory against unnecessary food costs and a step toward a more sustainable kitchen.

To get a handle on this, let's look at the most common ways a commercial griddle can quietly bleed your profits.

Commercial Griddle Hotspots for Food Waste Generation

The table below breaks down the primary ways commercial griddles contribute to food waste. These are the small, everyday issues that compound into significant financial losses over time.

| Waste Source | Common Cause on a Commercial Griddle | Resulting Waste |

|---|---|---|

| Incorrect Tool Usage | Using flimsy spatulas or turners that bend under weight. | Delicate items like fish fillets or large pancakes break apart on the commercial griddle, becoming unsellable. |

| Poor Seasoning | An unseasoned or improperly maintained commercial griddle surface. | Food sticks and tears during flipping, especially eggs, crepes, and seafood. |

| Overcrowding | Dropping too much cold product on the commercial griddle at once. | The commercial griddle's surface temperature plummets, steaming food instead of searing it, leading to greasy, unappealing results. |

| Carbon Buildup | Infrequent or improper cleaning between services on the commercial griddle. | Leftover debris transfers burnt flavors and creates an uneven cooking surface, causing hot spots and sticking. |

By recognizing these specific issues, you can start implementing targeted training and operational changes to stop the waste before it even starts.

You’ve got to pinpoint where things are going wrong before you can fix them. On the line, the most common commercial griddle-related culprits are:

- Using the wrong tools: A flimsy spatula that can’t handle a half-pound burger is going to break it on the commercial griddle. Mangled patties don't sell.

- A sticky surface: If your commercial griddle isn't properly seasoned, delicate foods like fish and eggs are guaranteed to tear. That's instant waste.

- Crowd control issues: Throwing too many frozen patties or cold ingredients on the commercial griddle at once kills the temperature. The result is greasy, steamed food, not the beautiful sear customers expect.

- Dirty griddle problems: All that black carbon buildup from the lunch rush? It transfers burnt, bitter flavors and makes food cook unevenly. Knowing how to clean a flat top griddle correctly is fundamental to quality and waste prevention.

Winning the Waste Fight Before the Food Hits the Commercial Griddle

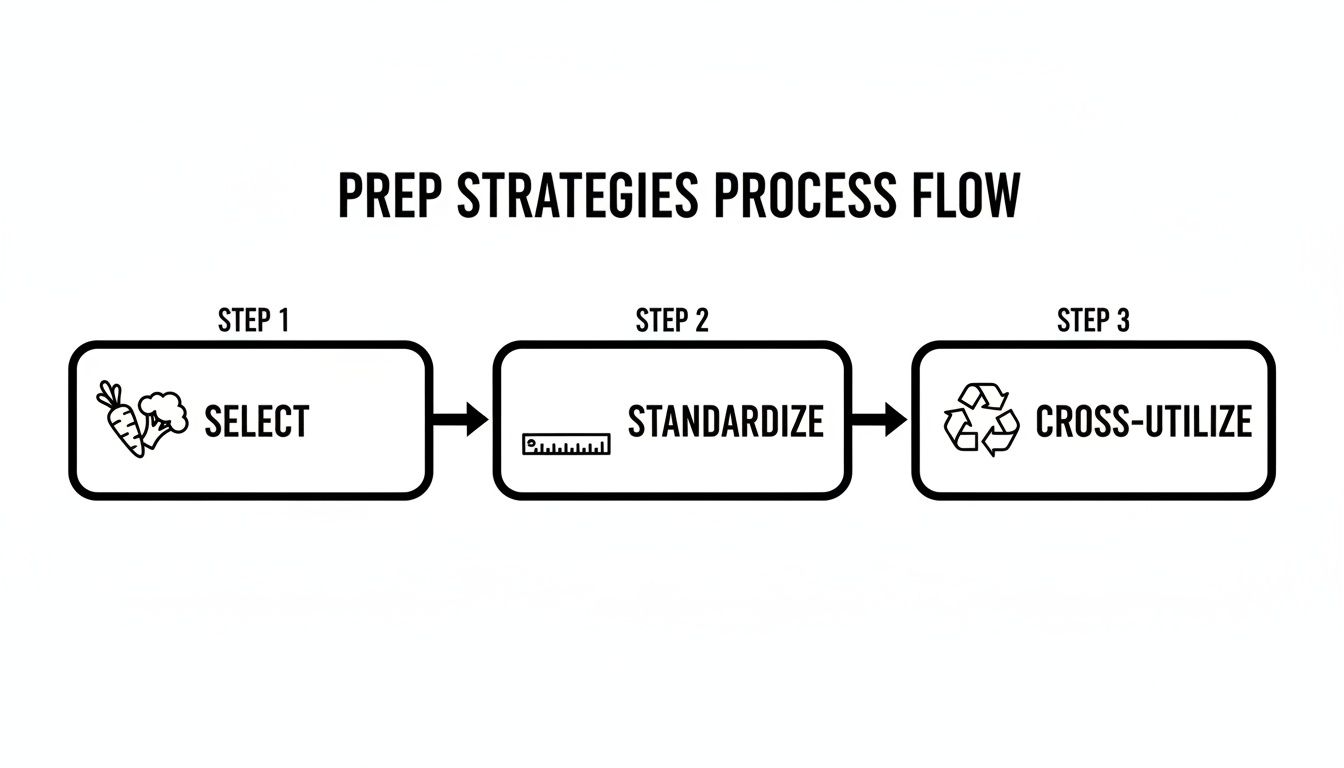

The battle against food waste is often won or lost long before the first sizzle on the commercial griddle. Smart, griddle-focused purchasing and meticulous prep work are the real foundations of a low-waste, high-profit kitchen. It’s all about being intentional from the moment you place an order to the second an ingredient is ready for the line.

This isn't just about buying ingredients; it's about sourcing them specifically for your commercial griddle's capabilities. Think about it: it's the difference between ordering a random case of steaks and selecting uniformly thick protein cuts that cook evenly and predictably on the commercial griddle, leaving almost no trim behind.

This simple strategy applies to everything you cook on your commercial griddle. If your diner is known for its hash browns, you'll want to choose potato varieties that actually hold their shape when shredded and crisped on the flattop. This tiny choice alone cuts down on mushy, unsellable product and keeps your quality consistent.

Standardize Everything for the Commercial Griddle

Precision during prep is non-negotiable if you're serious about reducing food waste from your commercial griddle. When every cook has a slightly different idea of what a "portion" is, you're just throwing money away. Standardized prep takes all the guesswork out of the equation.

You need to create clear, visual guides for all commercial griddle items and make sure your team sticks to them. This means setting exact weights for every burger patty, specific dice sizes for onions and peppers going into a Philly cheesesteak, and consistent thicknesses for sliced chicken. When every component is identical, cooking times become reliable, and the risk of burnt or undercooked food from the commercial griddle plummets.

The most effective way to control waste at the commercial griddle is to control what goes on it. Standardized prep ensures every item is set up for success, cooks predictably, and delivers a consistent experience for the guest.

Beyond the initial prep, your inventory management has to be on point. Seriously consider implementing effective food dating and labeling systems that are actually designed for the chaos of a real kitchen. First-In, First-Out (FIFO) can't just be a concept; it has to be a daily drill that keeps older, prepped ingredients moving to the commercial griddle first.

Cross-Utilization: Your Commercial Griddle's Secret Weapon

A commercial griddle is the perfect tool for turning potential waste into actual profit through cross-utilization. This is where your kitchen's creativity directly fattens your bottom line. Stop seeing trim and ends as trash—they are the building blocks for new, profitable menu items made on your commercial griddle.

The key is to train your team to see things this way. It’s not about salvaging scraps; it’s about squeezing every bit of value out of every single ingredient you paid for. Here are a few real-world examples of how to do this with your commercial griddle:

- Vegetable Ends and Trim: Those ends of onions, bell peppers, and zucchini that aren't pretty enough for fajita strips? Collect them. Dice them finely and use your commercial griddle to make a profitable "Garden Hash" side dish for your breakfast rush.

- Protein Trimmings: The off-cuts from portioning steaks or chicken breasts are pure gold. Give them a coarse chop, sear them hard on the commercial griddle, and boom—you've got the base for a signature breakfast scramble, a loaded omelet, or a savory filling for quesadillas.

- Day-Old Bread: Don't even think about tossing it. Slice that stale brioche or challah into thick pieces. They're perfect for making premium French toast on the commercial griddle, as their drier texture soaks up custard batter beautifully without turning to mush.

This mindset transforms your commercial griddle from just a cooking surface into a powerful recycling station that recaptures revenue. It's a non-negotiable part of any serious strategy for reducing food waste in restaurants.

Unfortunately, without these strategies, kitchen prep quickly becomes a massive source of loss. Prep-related activities like overproduction, trimming, and expired items are huge contributors to waste. The numbers are staggering: a shocking 84.3% of unused US restaurant food ends up in landfills. Research has even shown that nearly 18% of prepared food gets discarded, with much of that waste happening during prep and service. You can explore more data on restaurant food waste and its sources. Winning the fight before the food hits the commercial griddle isn't just good practice; it's essential for survival.

Mastering Your Commercial Griddle With Zoned Cooking

If you're still thinking of your commercial griddle in terms of "high, medium, low," you're leaving money on the table. A commercial griddle isn't just one big hot surface; it's a dynamic piece of real estate. To truly cut down on food waste, you have to master its geography. That's where zoned cooking comes in, and it's a total game-changer for your bottom line.

Zoned cooking is just what it sounds like: creating distinct, intentional temperature zones across the commercial griddle. Instead of fighting a uniformly screaming-hot plate, you build a workflow. Food moves from searing to cooking to holding, all on the same piece of equipment. It’s a simple shift that prevents the most common—and costly—commercial griddle mistakes, like torching a beautiful ribeye while you wait for the hashbrowns to finish.

Setting Up Your Commercial Griddle Cooking Zones

Getting your zones right is the first step. For most commercial units, this is as simple as setting your burners to different levels. A classic, effective setup on a commercial griddle usually looks something like this:

- The Searing Zone: This is your hottest section, cranked up to 400-450°F. It's all about getting that perfect, instant crust on steaks, burgers, or scallops. The goal isn't to cook it through, just to get that beautiful Maillard reaction going.

- The Cooking Zone: Your workhorse area, holding steady at a medium heat of 325-375°F. After a quick sear, proteins move here to cook through evenly without burning. This is also the go-to spot for things like pancakes, eggs, and veggies that need consistent, gentle heat from the start.

- The Warming Zone: This is your lowest temp area, hovering just over 200°F. Nothing gets cooked here. This is purely for holding finished items at a safe, servable temperature without turning them to rubber. It’s absolutely critical for timing up complex orders and making sure perfectly good food doesn't die in the window.

With these zones on your commercial griddle, you create a natural, efficient flow. A ticket comes in for a well-done steak and eggs. The steak hits the searing zone, then both items slide over to the cooking zone. If you need a minute, they can rest comfortably in the warming zone, ensuring everything is hot and ready at the exact same moment.

This is where thoughtful prep strategies really pay off.

When every item hitting that commercial griddle is uniform and prepped correctly, your zoned cooking becomes predictable, repeatable, and virtually waste-free.

Why Precise Temperature Control Is Non-Negotiable for Commercial Griddles

You can't manage what you don't measure. Guessing your commercial griddle's temperature is a one-way ticket to inconsistent food and a full trash can. That's why an infrared thermometer isn't a luxury; it's essential for any kitchen that's serious about quality control.

An infrared thermometer gives you an instant, accurate read of any spot on your commercial griddle. You can instantly verify that your zones are holding temp and spot any rogue hot or cold spots that could ruin an order. It takes the guesswork out of the equation and cuts down on re-fires.

The difference between a profitable commercial griddle station and a wasteful one is often just a few degrees. Precise temperature control stops waste before it happens by ensuring every single item is cooked correctly the first time.

Understanding Heat Draw on Your Commercial Griddle

Another skill that separates the pros from the rookies is understanding heat draw—how different foods suck the heat right out of your commercial griddle surface. If you drop a dozen frozen burger patties onto your cooking zone, you’ll watch the temperature plummet. Your searing surface suddenly becomes a steaming one, and you end up with greasy, grey pucks that nobody wants to eat.

To get a handle on heat draw on your commercial griddle:

- Don't overcrowd the griddle. Give items space to breathe. This lets the surface recover its heat and allows moisture to escape instead of steam.

- Temper your ingredients. When you can, let cold proteins sit out for a few minutes. Dropping ice-cold food on the commercial griddle causes a much more dramatic temperature drop.

- Use your ears and eyes. A healthy sizzle is the sound of success. If you hear a weak hiss and see steam, your commercial griddle's surface is too cold.

Mastering these thermal dynamics is crucial, especially when you consider different types of equipment. For instance, knowing the consistent heating you get from an electric griddle can help you choose a commercial griddle with faster heat recovery, minimizing those temperature swings and reducing waste even further.

When you truly understand how food interacts with heat on a commercial griddle, you can adjust on the fly and cook everything from delicate fish to stacks of pancakes perfectly, every single time. That level of control is fundamental to running a sustainable and profitable kitchen.

Smarter Cooking with Batches and On-Demand Griddling on Commercial Griddles

Overproduction is profit’s worst enemy, and your commercial griddle is often ground zero for the crime. We’ve all seen it: a line cook trying to get a jump on the rush by loading up the flat top with burgers an hour early. It might look efficient, but it's a one-way ticket to the trash can.

The real art lies in balancing smart batch cooking on your commercial griddle with the precision of cooking to order. It’s not about picking one over the other. It’s about knowing exactly which strategy to deploy for which menu item, at what time of day. This is how you keep ticket times down without sacrificing quality or throwing money away.

Finding the Sweet Spot Between Batch and On-Demand for Commercial Griddles

Let's get practical. Not everything should be fired on the fly from your commercial griddle, but batching everything is just as bad. The magic happens when you use your prep hours and commercial griddle space with a clear plan, guided by your sales forecast.

Think of it as building a flexible arsenal of griddle-ready components. Here’s what this hybrid approach actually looks like in a working kitchen:

- Breakfast Rush Scenario: Bacon is a prime candidate for par-cooking on a commercial griddle. During morning prep, you can griddle off sheets of bacon until they're about 75% cooked—the fat is rendered, but the strips are still pliable. Cool them, store them properly, and they can be crisped to perfection on the commercial griddle in less than a minute when a ticket comes in. This slashes ticket times and stops you from having a whole pan of bacon turning to dust under a heat lamp.

- Lunch Service Example: For your signature grilled chicken sandwich, you can sear off marinated chicken breasts on the commercial griddle in small, manageable batches. Cook them through, cool them down, and hold them. When an order hits, the cook just needs to slice the breast and give it a quick reheat on the commercial griddle for that fresh sizzle. It's infinitely smarter than cooking a dozen breasts from raw and praying they sell before they dry out.

- Dinner Service Precision: On the other hand, a beautiful piece of salmon or a high-end steak should never be batched on a commercial griddle. These items are cooked strictly to order, every single time. Their quality plummets too quickly, and the cost of just one unsold portion is far too high to risk.

Let Your Sales Data Drive Your Commercial Griddle

So how do you decide what to batch and what to cook fresh on your commercial griddle? The answer is already in your building: it’s in your POS system. Your sales data is a roadmap to intelligent production, taking all the guesswork out of the equation.

Stop treating your commercial griddle like a crystal ball. Use your sales data to tell it exactly what to cook and when. This is the single most effective way to kill overproduction waste.

Start digging into your hourly and daily sales reports. Do you consistently sell 30 orders of hash browns between 8 and 10 AM on Saturdays? That’s your batch target for the commercial griddle, right there. Do you only move five orders of the griddled shrimp scampi on a typical Tuesday night? That’s a clear signal to keep it strictly cook-to-order on the commercial griddle.

This focus is critical because the numbers are staggering. Food waste is responsible for 11% of global greenhouse gases. Here in the U.S., the foodservice industry throws out 40% of the nearly 60 million tons of food wasted annually. A huge chunk of this starts with good intentions, as studies show that 4% to 10% of all food a restaurant buys is wasted before it even gets to a customer, mostly from overproduction on equipment like commercial griddles. You can learn more about the environmental impact of restaurant waste on PMC.

Creating a Production SOP for Your Commercial Griddle Station

To make any of this stick, you need a simple Standard Operating Procedure (SOP) that every cook on the line can follow without thinking. It needs to clearly define what gets batched, what gets par-cooked, and what is always made fresh on the commercial griddle.

Your commercial griddle station SOP should be dead simple:

- Item Name: e.g., "Caramelized Onions"

- Production Method: Batch Cook on Commercial Griddle

- Batch Size: Tied to sales data (e.g., "1 quart for Monday lunch").

- Hold Time: The absolute max time the item can be held before quality suffers.

- Finishing Step: The action on the line (e.g., "Reheat portion on commercial griddle for 30 seconds before topping burger").

A system like this removes the guesswork, ensures every dish is consistent, and stops your commercial griddle from being a holding pen for future food waste. By marrying the efficiency of batch prep with the quality of on-demand cooking, you protect your bottom line and serve a fresher, better product.

How Your Commercial Griddle Choice Impacts Food Waste

It’s easy to think of your commercial griddle as just another piece of kitchen equipment, but it’s one of the most direct lines you have to either controlling or creating food waste. A cheap commercial griddle with unpredictable temperature swings and hot spots is a recipe for disaster. It will consistently churn out burnt, undercooked, or mangled food that goes straight into the trash.

Investing in the right commercial griddle isn't about having the fanciest gear—it's a smart business move that directly protects your bottom line. Every perfectly seared steak and flawlessly flipped pancake is a win against waste, and that only happens when your commercial griddle can keep up.

Key Commercial Griddle Features That Fight Waste

When you're shopping for a new commercial griddle, you're buying a quality control machine. For any kitchen that's serious about slashing waste, certain features are non-negotiable.

Here’s what to look for in a commercial griddle:

- Ultra-Precise Thermostatic Controls: This is a game-changer. Unlike manual griddles that make your cooks guess, thermostatic commercial griddles use sensors to lock in a specific temperature. That precision eliminates the hot and cold zones that are notorious for burning one side of a product while leaving the other raw.

- Rapid Heat Recovery: Throwing cold patties onto the commercial griddle causes the surface temp to plummet. A commercial griddle with fast recovery gets back to the set temperature in seconds, ensuring a consistent sear instead of a greasy, steamed mess.

- Even Heat Distribution: Look for commercial griddles with thick, heavy-duty plates—often 1-inch thick. This hefty construction is what guarantees heat spreads evenly across the entire surface. It means you can actually use every square inch of your commercial griddle and trust that everything will cook at the same rate.

If you want to get into the nitty-gritty of how these controls work, our article on thermostatic vs. manual griddles breaks down the differences so you can make the right call for your kitchen's commercial griddle.

To help you visualize how these features translate to real-world savings, here's a quick comparison.

Commercial Griddle Feature Impact on Food Waste

| Feature | How It Reduces Waste | Ideal For |

|---|---|---|

| Thermostatic Controls | Prevents burning and undercooking by maintaining a precise temperature on the commercial griddle. No more "hot spots" that ruin food. | Diners, breakfast spots, and any kitchen cooking delicate items like eggs, pancakes, or fish on a commercial griddle. |

| Thick Griddle Plate (1-inch) | Ensures even heat distribution across the entire surface of the commercial griddle. Food cooks uniformly, eliminating wasted portions. | High-volume kitchens, steakhouses, and burger joints that need consistent results from edge to edge on their commercial griddle. |

| Fast Heat Recovery | Minimizes temperature drops on the commercial griddle when adding cold food, preventing greasy or steamed results. | Any operation with a fast-paced line, especially those cooking from frozen (e.g., patties, hash browns) on a commercial griddle. |

| Grooved/Clamshell Design | Channels away excess grease and can cook both sides at once on the commercial griddle, reducing the chance of sticking or breaking during flipping. | Kitchens specializing in fatty proteins like bacon and sausage, or those looking to speed up cook times on their commercial griddle. |

Choosing a commercial griddle with these specs is a proactive step that pays for itself in saved product.

The Critical Role of Commercial Griddle Maintenance

Even the best commercial griddle on the market will become a waste machine if it's neglected. A dirty, poorly seasoned surface is the number one cause of food sticking, tearing, and picking up nasty, burnt flavors. You have to treat commercial griddle care as a core part of your waste reduction strategy, not just another closing-time chore.

A properly seasoned and maintained commercial griddle is your first line of defense against product loss. It creates a natural non-stick surface that ensures clean food release, protecting delicate items like fish and eggs from being destroyed during cooking.

Think about it: that carbon buildup from yesterday's service creates an uneven cooking surface and makes everything taste a little bit off. Regular maintenance of your commercial griddle isn't just about cleanliness; it's about protecting your equipment and the quality of every single dish that leaves the kitchen.

Your Practical Commercial Griddle Maintenance Checklist

Get your team into a simple but unbreakable routine. A consistent maintenance schedule keeps your commercial griddle in peak condition and stops food waste before it starts.

Daily Tasks (During and After Service)

- Scrape Constantly: Keep a griddle scraper handy and use it between orders on your commercial griddle. This simple step prevents gunk from building up during a busy shift.

- Degrease While It's Still Warm: After service, use a grill brick and a non-abrasive pad on the warm surface of the commercial griddle to easily scrub away grease and residue.

- Final Wipe and Re-Season: Once it's clean, wipe it down with a damp, clean cloth. Then, apply a very thin layer of cooking oil to protect the surface of the commercial griddle overnight.

Weekly Tasks

- Go for a Deep Clean: Use a dedicated griddle cleaner to break down any stubborn carbon deposits that daily scraping missed on your commercial griddle.

- Inspect and Empty the Drip Tray: Pull it out, wash it, and sanitize it. This prevents grease fires and pests for your commercial griddle.

- Check the Connections: For gas commercial griddles, give the hoses and connections a quick visual check for any cracks or signs of wear.

Sticking to this routine ensures your commercial griddle remains a reliable tool that makes you money, not a liability that adds to your food cost problems.

Quick Answers to Common Commercial Griddle Waste Questions

Even with a solid game plan, you're going to run into specific challenges on the line. When you're trying to cut down on food waste, the commercial griddle station seems to have a million little ways to trip you up. Here are some quick, no-nonsense answers to the questions I hear most from chefs and managers about keeping their commercial griddle ops lean.

My Commercial Griddle Has Hot Spots. How Do I Deal with That?

Uneven heat is public enemy number one for food waste. It burns one pancake while leaving its neighbor raw in the middle on your commercial griddle.

First things first, grab an infrared thermometer and actually map the surface. Find out exactly where your hot and cold zones are on your commercial griddle. If you're running a thermostatic commercial griddle, this is a huge red flag for a bad thermostat that needs to be replaced.

On a manual commercial griddle, this is just part of the game. You have to learn your equipment. Start thinking in terms of "cooking zones"—use the scorching hot spots for a hard sear, then slide the product over to a cooler area to finish cooking or to hold. Don't forget that a thick layer of carbon buildup can mess with heat distribution on a commercial griddle, so a deep clean can sometimes work wonders.

What’s the Best Way to Stop Food from Sticking to a Commercial Griddle?

Anything that sticks to that flat top is money straight into the trash can, especially when you're working with delicate stuff like fish or eggs on a commercial griddle. Your best defense, without a doubt, is a properly seasoned commercial griddle. A beautiful, well-maintained seasoning creates a natural non-stick surface that lets food release cleanly every single time.

It's a simple process:

- Clean it well after you're done, but never with harsh soaps that will strip away all your hard work on the commercial griddle's surface.

- Wipe a very thin layer of a neutral oil (canola is perfect) over the warm surface of the commercial griddle.

- Crank the heat until the oil just starts to smoke, then wipe off any excess. That process—polymerization—is what builds up that bulletproof, non-stick shield on your commercial griddle.

Should I Really Scrape the Commercial Griddle Between Every Single Order?

Yes. 100% yes. It takes five seconds and makes a world of difference for your commercial griddle.

When you leave old bits of food and burnt grease on the surface, you're setting a trap for the next ticket. Those crusty remnants will glue themselves to your fresh food, make it taste bitter, and wreck the presentation.

Make this a non-negotiable rule for the commercial griddle: keep a sharp, sturdy griddle scraper right there at the station, and make one or two quick passes between every single order. It's one of the easiest SOPs to implement and has a huge impact.

This little habit gives every dish a clean slate to cook on. The result is better, more consistent food from your commercial griddle and less waste.

Can I Throw Water on a Hot Commercial Griddle to Clean It?

Using a little water or a few ice cubes to deglaze a hot commercial griddle can be a slick move. The technique, often called "shocking," creates a blast of steam that lifts off really stubborn, cooked-on gunk. But you have to be careful here.

Dumping a ton of cold water on a screaming-hot commercial griddle can cause thermal shock. That's a fancy way of saying you could warp or even crack the steel plate over time. If you're going to use this trick, use just a tiny amount of water and stand back—that steam is no joke. For daily cleaning, a grill brick on a warm (not scorching) commercial griddle is a much safer bet.

Tired of inconsistent cooking torching your profits? Griddles.com has commercial griddles with 1-inch thick plates and precision thermostatic controls built for even heat and lightning-fast recovery. Find the right model to conquer food waste and boost your bottom line.