Learn how to clean a commercial griddle for peak performance

Before we get into the nitty-gritty of how to clean a commercial griddle, let's talk about why it's so critical. This isn't just about wiping things down. A proper cleaning and seasoning cycle is the only thing standing between your customers and hidden threats like carbon buildup, grease, and food debris. Ignoring this essential task can lead straight to health code violations, unexpected equipment breakdowns, and a tarnished reputation you’ve worked hard to build.

The Hidden Costs of a Dirty Commercial Griddle

It’s easy to forget about the griddle humming away on the line in a chaotic kitchen. It just cooks food, right? The reality is, that quiet workhorse can become a massive liability if you're not paying attention. A dirty commercial griddle isn't just a hygiene issue; it's a real threat to your business's safety, finances, and future.

The consequences go way beyond a little grime. Think about it: the surface of a griddle is constantly exposed to heat and food—the perfect environment for carbon buildup, which is a nasty, hard layer of burnt-on grease and food particles. It's also prime real estate for bacteria. These aren't just gross; they make your food taste burnt and can get you slapped with serious health code violations.

Financial and Reputational Damage

A failed health inspection isn't a slap on the wrist. It can mean hefty fines, a forced shutdown, and the kind of bad press that's incredibly hard to shake. Remember, the FDA considers your cooking surface a food-contact surface. That means it has to meet the same strict sanitary standards as your cutting boards and prep tables.

"A neglected griddle isn't just a maintenance issue; it's a direct threat to your operational integrity. The costs of equipment failure and reputational harm almost always exceed the time and resources needed for proper, consistent cleaning."

The financial pain doesn't stop there. A dirty griddle is an inefficient griddle. When carbon buildup creates an insulating layer, the heating elements have to work overtime just to heat the surface. This extra strain snowballs into bigger problems:

- Skyrocketing Energy Bills: A griddle fighting against carbon buildup is going to suck down a lot more gas or electricity, and you'll see it on your monthly utility bills.

- More Mechanical Breakdowns: Parts that are constantly overworked will wear out faster. That means more calls to the repair tech and more money spent on parts and labor.

- Inconsistent Cooking: As the griddle develops hot and cold spots, it can't cook food evenly. The last thing you want is to serve an undercooked burger during a Saturday night rush.

The Unseen Threat to Customer Health

The biggest risk, of course, is to your customers. And the science is pretty scary. In the high-volume world of food service, food safety studies have shown that uncleaned cooking surfaces can have bacterial growth rates up to 1,000 times higher than regularly sanitized ones.

This turns a simple cleaning task into a crucial investment in your business. It protects your patrons, your equipment, and your profits. Starting with high-quality, reliable commercial ice makers is step one. But consistently maintaining that equipment is the follow-through that keeps that investment paying off for years.

Assembling Your Commercial Griddle Cleaning and Safety Toolkit

Before you even think about cracking open that cleaning kit, you need to get your gear in order. Trust me, showing up unprepared is the fastest way to waste an hour of your life and potentially damage a very expensive piece of equipment. Having the right tools and chemicals ready to go is half the battle.

First, let's get one thing straight: cleaning and scraping are two completely different jobs. You can't skip one. Cleaning is the chemical act of breaking down grease and carbon. Scraping is the physical act of removing it. You have to clean and scrape effectively. You can't season a dirty surface.

Choosing the Right Chemicals

This is where people really mess up. Grabbing the wrong bottle from the chemical closet can destroy the griddle surface, void your warranty, and land you with a hefty repair bill. Your griddle's manual is your bible here; when in doubt, do exactly what it says.

You'll need two specific types of solutions:

- Griddle Cleaner: This is your carbon-buster. It’s a chemical solution designed to dissolve all that burnt-on grease and food. The magic you're looking for is food-safe.

- Griddle Polish/Conditioner: Once the carbon is gone, this is what protects the griddle surface. You need a food-grade oil or conditioner to season the griddle and prevent rust.

A critical warning: Never, ever use cold water on a hot griddle. This can cause thermal shock and warp or crack the griddle plate, making it useless. Allow the griddle to cool to the recommended temperature before cleaning.

Essential Tools and Safety Gear

Okay, chemicals are sorted. Now let's gather the rest of your kit. Having everything you need within arm's reach means no running back and forth while the griddle is at the perfect cleaning temperature. If you want a broader look at what to keep stocked for general upkeep, check out our complete guide to essential cleaning supplies for restaurants.

Here’s a quick-reference checklist to make sure you have everything you need before you start the job.

Your Complete Commercial Griddle Cleaning Checklist

This table breaks down the non-negotiable items for a safe and effective cleaning cycle. Get these organized in a dedicated bucket or caddy so your team can just grab it and go.

| Category | Essential Item | Primary Function |

|---|---|---|

| Chemicals | Food-Safe Griddle Cleaner | Dissolves grease and carbon buildup. |

| Food-Grade Seasoning Oil | Protects the griddle surface and prevents rust. | |

| Tools | Griddle Scraper | For removing heavy food debris and carbon. |

| Griddle Screen/Brick | For scrubbing the surface without scratching it. | |

| Squeegee & Microfiber Cloths | For applying solutions, rinsing, and wiping down surfaces. | |

| Non-Abrasive Scrub Pad | To gently remove stubborn grime from the griddle surface. | |

| Safety | Heat-Resistant Gloves | Protects hands from direct contact with the hot surface. |

| Safety Goggles or Glasses | Shields eyes from accidental splashes. |

Remember, protecting your people is just as important as protecting the machine. These chemicals and the hot surface can cause serious skin and eye irritation. Making Personal Protective Equipment (PPE)—especially gloves and safety glasses—a mandatory part of the process is a no-brainer. It prevents accidents and shows your team you care about their safety.

With this toolkit assembled, you’re setting your crew up for a successful, safe, and efficient clean every single time.

A Practical Guide to Deep Cleaning Your Commercial Griddle

Alright, you've got your toolkit ready, so let's get our hands dirty. This isn't just a quick scrape-down; we're talking about a proper deep clean that guarantees every single item your griddle produces is perfect and safe for your customers. We'll walk through the whole cleaning and seasoning process, hitting all the critical surface areas where carbon and grease love to hide.

The key here is to be methodical. If you rush through this or cut corners, you’ll either leave contaminants behind or, even worse, risk damaging your expensive griddle.

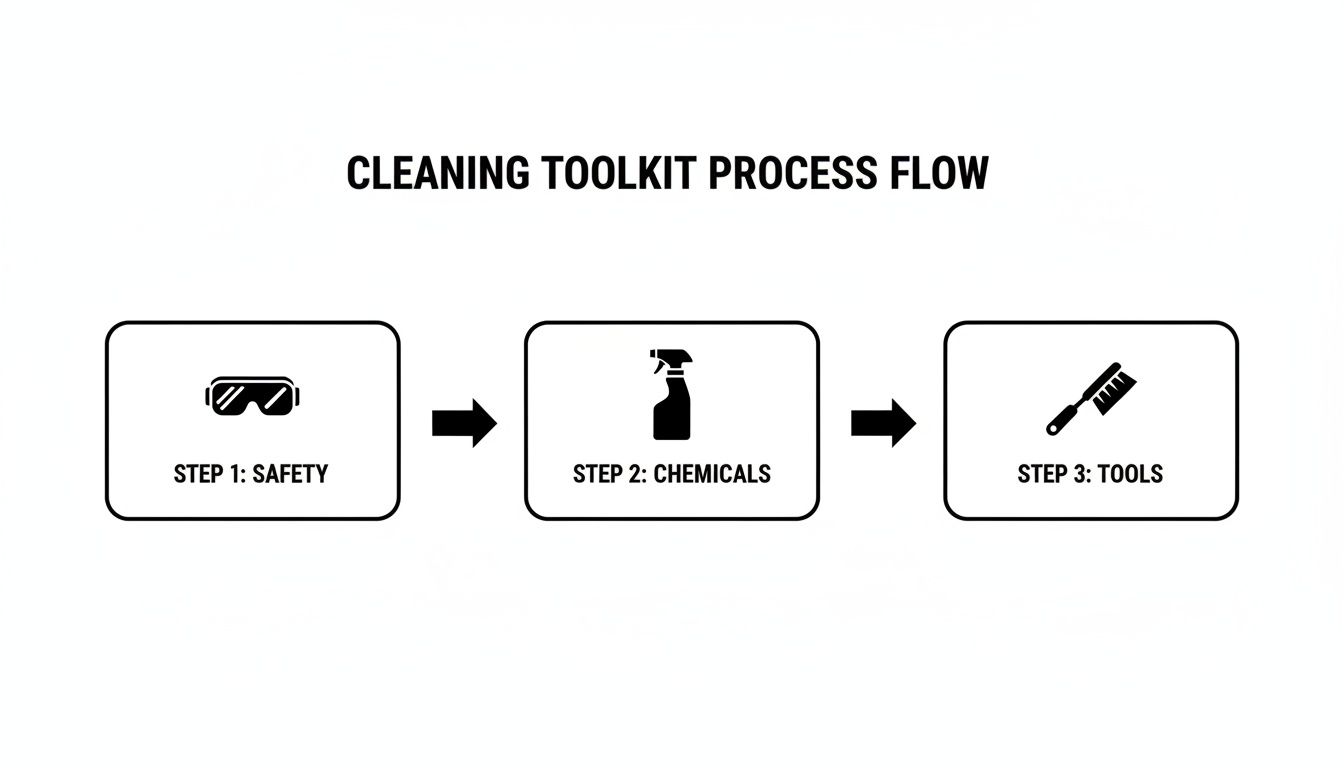

Think of this as your cheat sheet: safety first, then the right chemicals and tools. Get those three things right, and you're golden.

Getting Started: Safety and Prep Work

First things first, let's prep the griddle safely. Before a drop of cleaning solution touches anything, you need to cool it down and clear it out completely.

- Adjust the Heat: Turn the griddle down to around 300-350°F. The surface needs to be hot enough for the cleaner to work, but not so hot that it instantly evaporates.

- Scrape the Surface: Use your griddle scraper to remove all loose food debris and grease from the cooking surface. Push everything into the grease trap.

- Empty the Grease Trap: Carefully remove and empty the grease trap. This grease has to be disposed of properly, not poured down the drain.

Once the surface is clear, give the grease trough a quick check. Make sure it isn't clogged, so all the cleaning solutions can drain out properly later on.

The Elbow Grease Part: Application and Manual Scrubbing

With the griddle at the right temperature, it’s time to apply the cleaner. Most commercial griddle cleaners are designed for exactly this reason. Check your cleaner's instructions for the specifics on your model, but you’ll typically apply it evenly across the surface.

This is the high-traffic area where carbon builds up fast. Grab your griddle screen or brick and your cleaning solution, and get to scrubbing each area by hand. Really focus on the corners and edges—that’s where the worst of it hides.

Don’t just rely on the chemical cleaner to do all the heavy lifting. A little manual scrubbing is the only way to break loose that stubborn carbon buildup that chemicals alone can’t always dissolve.

If you have a spot that's especially nasty, let the cleaner sit for a few extra minutes while you work on other areas. That extra soaking time can work wonders on tough carbon deposits.

Running the Cleaning and Seasoning Cycles

After you've hand-scrubbed the entire surface, it's time to remove the cleaner and re-season the griddle.

Use a squeegee to pull all the dirty cleaning solution and lifted carbon into the grease trap. Now, rinse the surface with a small amount of clean water and squeegee it dry. Repeat this rinse step until the water runs clear and all chemical residue is gone.

Next, you'll season the griddle. Apply a thin layer of food-grade seasoning oil to the entire surface. Turn the heat up slightly and let the oil smoke for 15-20 minutes. This is the crucial step that creates a non-stick surface and protects the griddle from rust.

Think this is overkill? Recent studies found that a shocking 62% of restaurant surfaces tested positive for harmful bacteria. While a commercial kitchen is a different beast, it shows how easily these surfaces get contaminated. Proper seasoning is your best defense—according to industry protocols, a well-seasoned surface can inhibit bacterial growth and make daily cleaning much easier.

The Final Stretch: Wiping and Reassembly

Once the seasoning cycle is done, it's time for the final wipe. Turn off the griddle and let it cool completely. Any leftover oil should be wiped down with a clean, dry cloth. A well-seasoned griddle will have a smooth, dark, almost black finish.

When everything is cool, you can reassemble any final parts like the grease trap. The griddle is now ready for service. For more specific tips on different models, you can check out our other guides on thorough ice machine cleaning procedures.

By following this process, you’re not just cleaning an appliance—you're protecting your customers, upholding food safety standards, and making sure your equipment lasts for years to come.

Creating a Proactive Commercial Griddle Maintenance Schedule

That deep-clean feeling is great, but don't get too comfortable. If you’re only cleaning your griddle when you spot a problem, you’re already behind. A truly bulletproof strategy is all about getting ahead of the game with a proactive, consistent schedule. You have to stop issues like carbon buildup before they even get a foothold.

This isn't about creating more work for your team. It's about making the work you do count. A simple, well-defined routine prevents minor buildup from snowballing into a major weekend-killing project. It also extends the life of your griddle and makes sure every single burger is perfect.

Your Essential Maintenance Cadence

Building a solid routine is all about rhythm and frequency. You wouldn't change the fryer oil once a year, right? Same principle. Different tasks need to be done at different intervals to keep your griddle humming. Think of it as layers of defense against contamination and wear.

Here’s a practical framework you can adapt for your own kitchen:

- During Service: These are the quick, five-second jobs. Scrape down the surface between orders to prevent buildup.

- Daily Clean: At the end of every shift, perform a thorough scrape and wipe-down with a griddle brick or screen while the surface is still warm. Empty and clean the grease trap.

- Weekly Deep Cleans: This is the big one—the full chemical cleaning and re-seasoning cycle we just walked through. This is your primary, non-negotiable defense against heavy carbon buildup.

- Semi-Annual Inspections: Twice a year, it’s time to play detective. Check the thermostat calibration to ensure accurate temperatures. Inspect gas lines or electrical connections for safety.

Your schedule is a living document, not a stone tablet. A high-volume diner flipping burgers all day will need to clean far more often than a restaurant that only uses its griddle for a few menu items. Be prepared to adjust your timeline based on what your kitchen environment throws at you.

Customizing Your Cleaning Frequency

No two kitchens are identical, so a one-size-fits-all cleaning plan just won’t cut it. A few key factors will dictate how often you need to run a full cleaning cycle. The type of food you cook is a huge one; sugary marinades and sauces will caramelize and burn much faster than plain burgers.

The griddle material itself plays a massive role, too. Is your griddle steel or chrome? Chrome surfaces are more delicate and require different cleaning methods and frequencies than standard steel.

In the commercial food service world, where North America accounts for 37.8% of the $5.3 billion global commercial cooking equipment market, routine maintenance isn't just a good idea—it's often a health code requirement. The numbers don't lie: industry data shows that sticking to a mandated daily clean can slash equipment downtime by a whopping 40%. Plus, keeping the surface clean and efficient can cut energy use by 15-20% and extend the griddle's lifespan by 25-30%. You can dig deeper into these trends in this detailed market analysis.

Promoting Accountability with a Cleaning Log

Let's be real: the best schedule in the world is useless if no one follows it. The secret weapon here is a simple cleaning log posted right on or next to the griddle. It’s all about consistency and accountability.

This doesn't need to be complicated. A basic chart with columns for the date, the task performed (e.g., "Daily Scrape," "Weekly Deep Clean"), and the initials of the employee who did it is all you need. This simple piece of paper turns an abstract plan into a concrete set of responsibilities. It makes it dead simple to track who did what and when, which is a lifesaver if you ever need to troubleshoot a problem. It’s the final piece of the puzzle for a maintenance system that actually works.

Troubleshooting Common Commercial Griddle Cleaning Issues

Even when you stick to a perfect cleaning schedule, your commercial griddle can still throw you a curveball. Nothing's more frustrating than a lingering smell, sticky spots, or uneven heat, especially in the middle of a dinner rush.

Before you grab the phone to call for a service tech, take a breath. Many of these post-cleaning gremlins are things you can diagnose and fix yourself with a little detective work. Think of this as your first line of defense—a way to save yourself a costly service call.

Diagnosing Sticky or Smelly Food

So, you just ran a full cleaning and seasoning cycle, but that first batch of pancakes comes out tasting off or sticks to the surface. This is probably the most common complaint I hear, and it almost always comes down to two things.

First, and most likely, is inadequate rinsing. If even a tiny bit of chemical cleaner is left behind, it's going to mess with the taste and smell of your food. The fix is simple but critical: rinse the griddle again with clean water. You'll need to manually flush the surface with fresh, clean water until every trace of that chemical is gone.

The other culprit could be your seasoning. If the oil layer is too thick or uneven, it can become sticky and gummy instead of creating a slick, non-stick surface. Sometimes, a deep clean can strip off old seasoning, requiring a fresh, careful re-seasoning process. As a general rule, you should be applying a very thin layer of oil.

It's a sobering thought, but uncleaned commercial units are linked to 25% of foodborne illness complaints in U.S. restaurants each year, according to FDA data. Proper cleaning isn't just about non-stick surfaces; it's a critical food safety protocol. You can learn more about the ice maker market's emphasis on safety to see how seriously the industry takes this.

Solving Hot and Cold Spots

Another classic headache is when your griddle starts cooking unevenly. This is a dead giveaway that you've got a surface problem, and the usual suspect is carbon buildup. Even after a cleaning cycle, tiny carbon deposits can remain, creating an insulating layer that prevents heat from transferring properly.

If you see this happening, here’s what to do:

- Inspect the Surface: Turn the griddle off and let it cool completely. Look at the surface under a bright light. Do you see any dull, black patches? Use a griddle stone or screen to gently scrub these areas again.

- Check the Thermostat: Ensure the thermostat probe is clean and making proper contact. A dirty probe can't read the temperature correctly, leading to those frustrating hot and cold spots.

This is exactly why that manual scrubbing step is so important. The chemical cleaner is good, but it can't always break loose every single piece of stubborn carbon.

The Food That Won't Stop Sticking

Okay, this one is maddening. You've done everything right, the griddle is spotless, but food just sticks, mocking you. It feels like a surface defect, but it’s almost always an issue with the seasoning layer.

A well-seasoned griddle should be non-stick. If food is sticking, it usually means one of three things:

- The Seasoning is Gone: The cleaning process might have been too aggressive and stripped the seasoning off completely. The surface will look dull and grey instead of dark and shiny.

- An Incomplete Seasoning: The seasoning cycle might have been too short or the temperature too low. Your best bet is to just run another full seasoning cycle from start to finish.

- The Griddle Needs Resetting: Not in a technical sense, but you need to start over. Check your owner's manual for the initial seasoning procedure—it's often a simple process of applying oil and heating the griddle to a specific temperature for a set amount of time.

By working through these common issues methodically, you can handle most post-cleaning hiccups yourself and get your griddle back to cooking perfect food without missing a beat.

Questions We Hear All the Time About Cleaning Commercial Griddles

Even when you have a solid process, questions are bound to come up. When you're in the middle of a busy shift, you need quick, clear answers. Here are some of the most common things we get asked by kitchen managers and staff about keeping their griddles spotless.

Let's clear up some of that confusion right now.

How Often Should I Really Be Cleaning My Griddle?

This is the golden question, and the honest-to-goodness answer is: it depends on your kitchen.

The absolute bare minimum for a full-on chemical clean and re-seasoning is at least once a week. But your environment really calls the shots. Don't just set it and forget it.

You absolutely need to clean it more often if you’re dealing with:

- Sugary Sauces: If your menu has a lot of glazes or marinades, carbon will build up fast and can literally ruin your griddle.

- Airborne Grease: Is your fryer right beside the griddle? All that airborne grease is fuel for a sticky, grimy surface.

- High-Volume Use: The more food you're cranking out, the more stress the griddle is under. More use means it needs more love.

For most restaurants we work with, a daily deep clean is the safest bet. It’s way easier to stay ahead of the problem than to fix a full-blown carbon situation.

Can't I Just Use Soap and Water?

Please don't. While that trick might work for your pan at home, a commercial griddle is a different beast entirely.

Soap is often too weak for the heavy-duty carbon that builds up in these units. More importantly, it will completely strip the seasoning off your griddle, which means you risk rust and food sticking—two of the most expensive problems to fix. And regular water? It won't cut through the grease at all.

Stick with the pro stuff. Always use manufacturer-approved, food-safe griddle cleaners and food-grade seasoning oils. They're formulated to knock out carbon and grease without eating away at the sensitive surface of your machine. It’s the only way to protect your investment and keep your food safe.

What’s the Difference Between Cleaning and Seasoning Again?

This is a huge one, and getting it wrong is a common ticket to a failed health inspection. They are two different steps, and both are non-negotiable.

- Cleaning: This is all about the physical stuff. You’re scrubbing away carbon buildup, grease, and any visible grime. Think of it as clearing the battlefield.

- Seasoning: This is creating the protective layer. A food-grade oil is used to create a non-stick surface and protect the griddle from rust.

You always clean first, then season. Why? Because you can't season a dirty surface. That layer of grime acts like a shield, preventing the oil from bonding with the metal. This one-two punch is the core of doing the job right.

At Griddles.com, we know that great food starts with reliable equipment. Whether you're launching a food truck or outfitting a five-star restaurant, we've got the top-tier commercial griddles, fryers, and refrigeration you need to succeed. Check out our full catalog and get free, fast shipping on every single order at https://griddles.com.