restaurant cleaning supplies: Your Guide to a Spotless Commercial Griddle

A commercial griddle is the heart and soul of many kitchens, but keeping that workhorse clean takes more than just a little elbow grease. You need a specific set of restaurant cleaning supplies built for the job. Your go-to arsenal breaks down into three simple categories: manual scraping tools, powerful cleaning agents, and the right personal protective equipment (PPE). Nailing these basics is the first real step toward a perfectly clean, high-performing cooking surface.

Your Essential Commercial Griddle Cleaning Toolkit

Think of cleaning your griddle less like a chore and more like essential maintenance for your kitchen's MVP. A chef wouldn't use a butter knife to chop onions, and you shouldn't use the wrong tools to tackle baked-on grease and carbon. Putting together the right kit is the foundation for everything, from a quick daily wipe-down to a deep weekly scrub.

Every piece of equipment has its purpose. Trying to use a standard kitchen sponge on a hot griddle is not just ineffective—it's downright dangerous. The right supplies, on the other hand, work in harmony to make the process faster, safer, and way more effective, ensuring your griddle cranks out perfect orders day after day.

The Tools for Manual Scraping and Scouring

Before any chemicals even enter the picture, you have to do the heavy lifting. That means physically removing those thick, stubborn layers of food debris and carbonized grease. This is where specialized manual tools really shine, as they're built to be tough on gunk but gentle on your griddle's steel surface.

The absolute cornerstone here is the heavy-duty griddle scraper. This isn't your everyday spatula. It’s a purpose-built tool with a sharp, rigid blade designed to shear off thick carbon deposits while the griddle is still hot. For a closer look at what separates a great scraper from a flimsy one, check out our guide on picking the perfect flat top grill scraper.

Your other key players in this stage are:

- Griddle Bricks or Pumice Stones: These porous, abrasive blocks are like sandpaper for your flat top. They're fantastic for polishing the surface after a good scrape, getting rid of any lingering tough spots or discoloration without gouging the metal.

- Griddle Screens and Pads: Think of these as industrial-strength scouring pads. You pop them under a special holder, and they give you the aggressive cleaning power needed to lift that stubborn, baked-on crud that scrapers sometimes miss.

To keep things simple, here's a quick rundown of the essential tools you'll need.

Essential Commercial Griddle Cleaning Supplies

| Supply | Primary Function | Best Used For |

|---|---|---|

| Griddle Scraper | Physical removal of heavy debris | Daily cleaning while the griddle is hot. |

| Griddle Brick | Polishing and removing tough stains | After scraping to restore the surface shine. |

| Griddle Screen/Pad | Aggressive scouring of baked-on residue | Deep cleaning for stubborn, stuck-on grime. |

| High-Temp Cleaner | Chemical breakdown of grease and oil | After scraping to dissolve what's left. |

| Heat-Resistant Gloves | Protecting hands from burns/chemicals | Anytime you are working on a hot griddle. |

| Safety Goggles | Protecting eyes from splashes | During the entire cleaning process. |

Having these items on hand makes the entire process smoother and ensures you’re prepared for any level of cleaning, from a quick touch-up to a full restoration.

Powerful Yet Safe Cleaning Agents

Once you've scraped away the bulk of the debris, it's time to let chemistry do the hard work. The right cleaning agents are formulated to dissolve the polymerized oils—that’s the scientific term for the sticky, glue-like grease that bonds carbon to your steel.

A rookie mistake is grabbing a generic, all-purpose degreaser. Commercial griddle cleaners are specially designed to work at high temperatures, breaking down tough grease without creating hazardous fumes or leaving behind unsafe chemical residues.

The main product you need is a high-temperature griddle cleaner. This liquid is applied right onto the hot surface, where it immediately foams up to lift and dissolve any remaining grease. Always look for formulas that are certified food-safe and non-fuming to protect both your crew and your customers. To finish the job, a simple food-safe surface sanitizer makes sure the griddle is pristine and ready for the next service.

Essential Personal Protective Equipment (PPE)

Let’s be clear: working with a blazing hot surface and powerful chemicals requires safety gear. This isn't negotiable. Cleaning a commercial griddle means dealing with temperatures that can easily exceed 350°F (177°C), creating serious burn risks from the surface itself, hot steam, and splashing liquids.

Your must-have PPE includes:

- Heat-Resistant Gloves: Standard latex or nitrile gloves will melt in an instant. You need heavy-duty, insulated gloves that can protect your hands and forearms from intense heat and chemical contact.

- Safety Goggles or a Face Shield: Splattering grease and cleaning chemicals are a huge risk to your eyes. Goggles are a critical piece of safety equipment that provides a seal against any dangerous splashes.

- Apron: A waterproof, heavy-duty apron is your first line of defense, protecting your uniform and skin from hot liquids and chemical spills.

Choosing the Right Griddle Cleaners and Chemicals

Once you’ve scraped away the big stuff, chemicals are your best friend. But picking the right cleaner for your commercial griddle is like having the right key for a lock. Trying to use a generic degreaser on that stubborn, cooked-on gunk is like trying to open a deadbolt with your car key—it won't work, and you might break something.

That tacky, baked-on residue you see after a long shift isn't just grease. It’s polymerized oil, a tough, almost plastic-like layer that forms when cooking oils get heated over and over. You need specific restaurant cleaning supplies that are built to break down these strong chemical bonds without wrecking your griddle’s cooking surface.

Demystifying Griddle Cleaning Agents

Walking down the chemical aisle can be overwhelming, but it really just comes down to a few key players. Each has a specific job, and using them in the right order is the secret to getting a perfectly clean, food-safe surface.

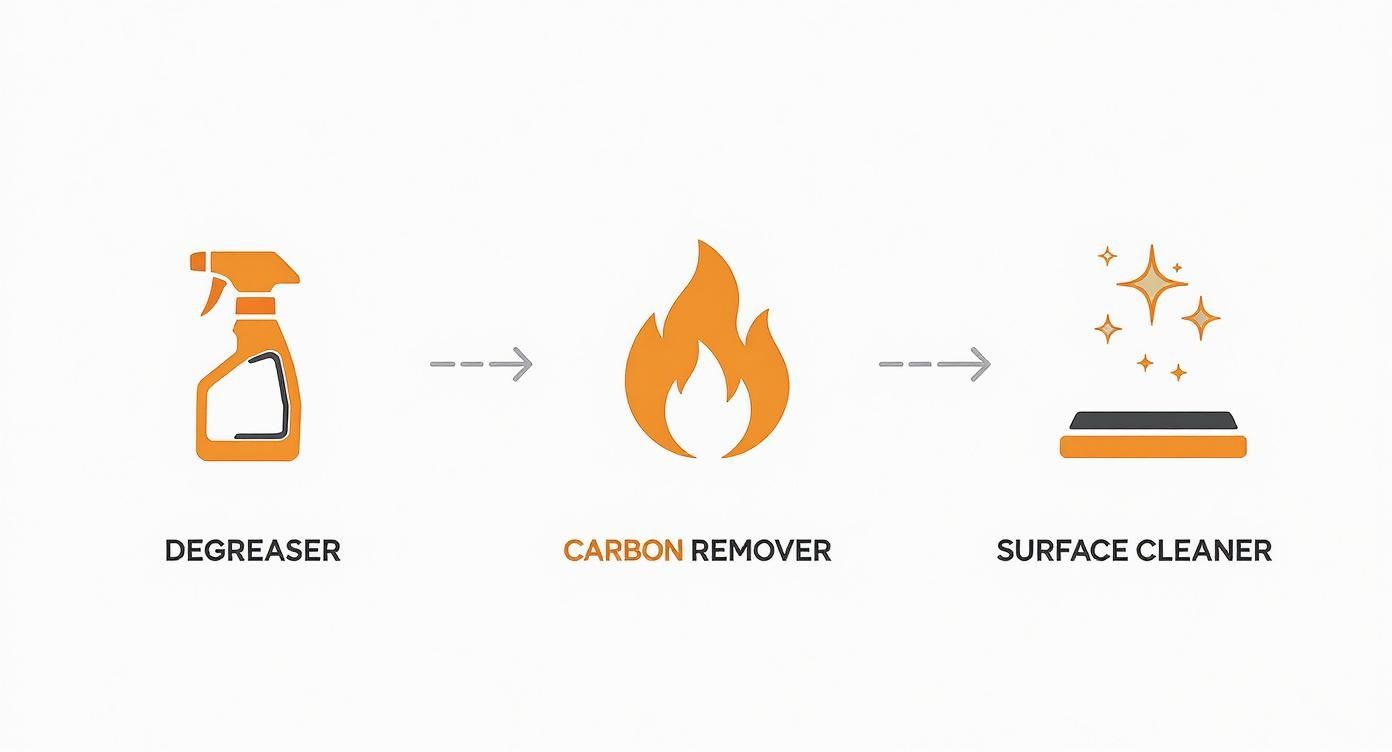

Think of it as a three-stage attack plan for grime:

- Degreasers: These are your frontline soldiers. They're designed to cut through fresh, liquid grease right away. Most are alkaline-based and work by breaking up oils so you can just wipe them away. The problem is, they don't have much power against the really tough, carbonized layers.

- Carbon Removers: Call in the special forces. When grease gets cooked on for hours, it turns into a hard, black coating called carbon. Carbon removers are the heavy hitters, often with a high-pH formula designed specifically to dissolve these burnt-on messes.

- Food-Safe Surface Cleaners: This is your final wipe-down. After all the heavy-duty cleaning is done, a food-safe cleaner (usually with a neutral pH) gets rid of any chemical residue. This step neutralizes the surface, making sure it's sanitary and ready for food.

Grab the wrong product, like an acidic cleaner on a steel surface, and you could end up with pitting and corrosion. That’s permanent damage to your equipment.

Why pH Levels Are Critical

The pH scale is the secret language of cleaning chemicals. It simply measures how acidic or alkaline something is. Anything below a pH of 7 is acidic, 7 is neutral, and above 7 is alkaline. For griddle cleaning, almost all the real work is done by alkaline cleaners with a high pH.

Why? Because alkalinity is a beast at breaking down organic stuff like fats, oils, and proteins—exactly what you're trying to clean. A good high-temp griddle cleaner usually has a pH somewhere between 11 and 13, giving it the muscle needed to dissolve that polymerized grease.

Here's a simple rule to remember: Alkaline cleaners for organic messes (grease, carbon). Acidic cleaners for inorganic messes (rust, limescale). Never, ever use an acidic cleaner for daily griddle degreasing.

Matching the Cleaner to Your Griddle Type

The material your griddle is made of will tell you exactly what kind of chemical you can use. The two most common types, steel and chrome, have totally different rules.

- Steel Griddles: These are the workhorses of the kitchen. They’re tough and can handle more aggressive, high-alkaline cleaners and even abrasive tools like griddle bricks. Because the surface is porous, they need to be properly seasoned after a deep clean to protect the metal.

- Chrome Griddles: A chrome-plated griddle has a delicate, non-porous surface that gives it great non-stick properties. You must never use abrasive pads or harsh, caustic chemicals on chrome. You'll scratch the plating and ruin the griddle for good. Stick to cleaners that are specifically labeled as "safe for chrome."

At the end of the day, reading the product label isn't optional. Manufacturers create their restaurant cleaning supplies for very specific jobs and materials. Using the wrong one is just a fast way to damage expensive gear, put food safety at risk, and create headaches for your team.

The Daily Griddle Cleaning Ritual Step by Step

A perfectly seasoned griddle doesn't just happen. It’s the direct result of a consistent, repeatable process you follow every single day. Stop thinking of this as a chore—it's a critical investment in your equipment's lifespan and the quality of your food. Following these steps guarantees that every dish is free from the ghosts of services past.

This isn’t about just scrubbing a dirty surface at the end of a punishing shift. It’s a proven, methodical process that protects the steel and preps it for the next day's battle. The goal here is to create a simple blueprint your team can follow without thinking, turning a dreaded task into a quick, easy routine.

Step 1: Scrape While the Griddle Is Hot

The second the last order goes out, the cleaning begins. Your griddle should still be hot, somewhere in the 300-350°F (150-177°C) range. That heat is your secret weapon, keeping all the grease and burnt-on bits loose and ready to go.

Grab a heavy-duty griddle scraper. Hold it at a low angle, maybe 30 degrees, and push all that debris away from you and into the grease trap. That low angle is crucial—come in too steep, and you'll gouge the metal, creating tiny scratches where carbon will build up later. Just work your way across the whole surface until the major gunk is gone.

Step 2: Apply a High-Temperature Degreaser

With the big stuff out of the way, it's time to deal with that sticky, slick layer of cooked-on oil. This is where a specialized high-temp griddle cleaner earns its keep. These professional restaurant cleaning supplies are made to work on hot surfaces, breaking down the stubborn grease that a scraper can’t touch.

Pour the right amount of cleaner directly onto the hot surface. You'll see it bubble and foam up immediately—that's the chemical reaction doing its job, lifting the grime right off the steel. Use a non-abrasive, heat-resistant pad on a long-handled holder and work the cleaner across the griddle in small circles.

Step 3: Neutralize and Squeegee the Surface

Let the cleaner sit for a minute or two (check the manufacturer's instructions to be sure), then it's time to neutralize it. Pour a little warm water or club soda on the griddle. You’ll get a big burst of steam that lifts any leftover chemical residue and loosened crud.

Now, take a griddle squeegee and pull all that liquid from the back to the front, right into the grease trap. Do it again until the water you're pulling off is completely clear. You need a clean, dry surface for the next step.

Do not skip the neutralization step. Leaving chemical cleaner residue on the griddle surface is a major food safety hazard. A thorough water rinse and squeegee ensures the flat top is completely clean and safe for the next cooking service.

This infographic shows the simple but powerful sequence of chemicals used in the cleaning process.

This shows that a real clean is a multi-stage process. You start with a powerful degreaser and finish with a surface cleaner to get that food-safe finish.

Step 4: Polish and Final Wipe Down

The griddle's clean, but let's give it a quick polish to restore that smooth finish. Take a griddle brick or pumice stone and gently rub the surface, always moving with the grain of the metal. This gets rid of any last bits of discoloration or minor blemishes without hurting the steel.

After that, wipe the whole thing down with a clean, damp cloth to get rid of any dust from the brick. Then, dry it completely with a clean towel. For a deeper dive into the tools and techniques, you can learn more about how to clean a flat top griddle in our complete guide.

Step 5: Season the Griddle Surface

This is the final, non-negotiable step: re-seasoning. Seasoning creates that beautiful, non-stick surface that prevents rust and makes sure tomorrow's food slides right off. If you skip this, all that cleaning was for nothing.

Here’s how to do it right:

- Turn the heat up to medium-high.

- Put a very thin layer of high-smoke-point oil (canola or flaxseed work great) on a clean, lint-free cloth and wipe it over the entire surface.

- Let the griddle heat up until the oil just starts to smoke.

- As soon as you see that wisp of smoke, kill the heat and wipe off any extra oil.

That's it. Your griddle is now clean, protected, and ready to go for another service.

Advanced Deep Cleaning and Carbon Removal

Even if your daily cleaning routine is perfect, every commercial griddle eventually meets its worst enemy: carbon buildup. Those daily wipe-downs are great for managing the fresh grease, but over time, tiny layers of oil polymerize—they basically bake into a rock-hard black crust. This isn't just ugly; it screws up your griddle's performance, creating hot spots that burn food, tainting flavors, and forcing the equipment to work harder just to stay hot.

Think of it this way: daily cleaning is like brushing your teeth. It's absolutely essential for day-to-day hygiene. But a deep clean? That's your trip to the dental hygienist. It's a more serious, periodic cleaning that gets rid of the stubborn plaque that daily brushing just can't touch, bringing the surface back to its original, peak-performance condition.

Moving Beyond Daily Maintenance

Your weekly or bi-weekly deep clean is when you break out the heavy-duty restaurant cleaning supplies. This is way more than a quick scrape and wipe. We're talking about potent, high-temperature chemical cleaners designed specifically to dissolve the kind of baked-on carbon that just laughs at your daily efforts.

This isn't about scrubbing harder; it's about using smarter chemistry to break the chemical bonds that have fused that gunk to your steel. The whole point is to strip everything off—all the seasoning and carbon—to get right back down to the bare metal. From there, you can build a fresh, clean cooking surface from scratch.

Carbon buildup is like putting a winter coat on your griddle. One study found that even a thin layer of carbon can slash heat transfer efficiency by over 10%. That forces you to crank up the thermostat, wasting energy and leading to unevenly cooked food.

A scheduled deep clean is a non-negotiable part of any solid preventative maintenance plan. You can dive deeper into building a complete strategy for all your gear in our guide to commercial kitchen equipment maintenance.

The Deep Cleaning Protocol Step by Step

Tackling a deep clean requires a methodical game plan, and safety is priority number one because of the powerful chemicals you'll be using. Ventilation is absolutely critical. Make sure your exhaust hoods are running on high and you've got good airflow in the area.

- Heat the Griddle: Just like your daily routine, you want a hot surface, usually somewhere between 300-350°F (150-177°C). That heat is what activates the powerful chemicals in the deep cleaner.

- Scrape Away Loose Debris: Give the griddle a really good initial scrape to get rid of any thick, chunky carbon. This clears the deck so the chemical cleaner can get to work on the bonded layers underneath.

- Apply a Carbon-Removing Cleaner: Now's the time for the specialized stuff. Grab a product made for carbon removal, not just a standard degreaser. These cleaners are often thick gels that cling to the surface and have a high pH to melt away that polymerized fat.

- Let the Chemical Work: Give the cleaner time to do its job. Follow the manufacturer's directions, but it's typically 5-10 minutes. You’ll literally see it start to bubble and break down the black crust.

- Scour the Surface: With a griddle screen or a tough scouring pad, start scrubbing the whole surface in circular motions. The carbon will start lifting away, revealing the steel below. Be prepared to use some elbow grease here.

- Neutralize and Rinse Thoroughly: Douse the surface with warm water to stop the chemical reaction. Use a squeegee to pull all that disgusting black liquid into the grease trap. You'll need to repeat this rinse-and-squeegee step until the water running off is completely clear.

- Final Polish and Seasoning: Once the griddle is clean, dry, and cool enough to handle, grab a griddle brick and polish away any lingering discoloration. To finish, you have to do a full re-seasoning to protect the bare metal and get that non-stick surface back.

Bringing a Neglected Griddle Back to Life

So, what happens if you take over a kitchen and find a griddle that looks more like a charcoal briquette than a piece of cooking equipment? First, don't panic. The process is pretty much the same as a deep clean, but you might need to do it two or three times to cut through years of neglect.

For those really nasty, heavily carbonized surfaces, you may need to apply the carbon remover, let it sit, and then use a stiff, sharp scraper to carefully chip off the thickest deposits before you even think about scouring. It’s a tough job, no doubt. But with the right restaurant cleaning supplies and a bit of persistence, you can bring a seemingly hopeless griddle back from the dead and turn it into a clean, efficient workhorse for your kitchen.

Safety Protocols for Handling Griddle Cleaning Supplies

Let's be blunt: the chemicals that can strip baked-on carbon off a hot griddle are seriously potent. You have to treat them with respect. Mishandling these restaurant cleaning supplies can cause nasty chemical burns, fill your kitchen with dangerous fumes, or lead to accidental contamination. What starts as a simple cleaning task can quickly become a major hazard.

That's why having clear, non-negotiable safety rules isn't just about passing a health inspection. It’s about protecting your crew.

Think of your chemical storage area like a biohazard zone. You need a hard line between cleaning agents and anything edible. This simple discipline prevents cross-contamination that could lead to health code violations or, far worse, make a customer sick. A real culture of safety starts when everyone treats these chemicals with the caution they deserve.

Understanding Your Chemical Arsenal with SDS

Every bottle of cleaner and degreaser you buy comes with a critical document: the Safety Data Sheet (SDS). The SDS isn’t just fine print; it's the playbook for that specific chemical. It tells you exactly what’s in it, what the risks are, what protective gear to wear, and the right first-aid steps if something goes wrong.

Training your staff to actually read and understand an SDS is a foundational piece of kitchen safety. It gives them the knowledge to use chemicals the right way and react quickly and correctly in an emergency.

Keep a binder with the SDS for every single chemical you use in an obvious, easy-to-reach spot. When an emergency hits, nobody has time to go on a scavenger hunt for that information. This one simple habit is a cornerstone of workplace safety.

Proper Storage and Labeling Practices

Safe chemical handling doesn’t start when you pour the cleaner. It starts with an organized and secure storage system designed to head off accidents before they happen. The golden rule is simple: chemicals and food never, ever mix.

Set aside a specific, locked cabinet or a separate, well-ventilated storeroom just for griddle cleaning supplies. This area needs to be far away from food prep surfaces, walk-ins, and dry storage.

Stick to these essential storage rules:

- Keep Chemicals in Original Containers: Never, ever transfer cleaners into unmarked spray bottles or old food containers. The original bottle has all the crucial warnings and instructions you lose the second you pour it into something else.

- Check for Leaks and Damage: Give your chemical containers a quick once-over regularly. Look for cracks, loose caps, or any signs of leaks. A single damaged bottle can create a hazardous spill and a dangerous slip-and-fall risk.

- Ensure Proper Ventilation: Your chemical storage area needs good airflow. This prevents the buildup of fumes that can be harmful when inhaled over time.

Personal Protective Equipment The Non-Negotiables

When your team is cleaning a hot griddle, they're facing multiple threats at once: thermal burns from a 350°F surface, chemical burns from splashing liquids, and serious eye damage. Personal Protective Equipment (PPE) is their armor against these dangers. It’s not optional.

Here’s the mandatory PPE for griddle cleaning:

- Heat-Resistant Gloves: These are non-negotiable for protecting hands and forearms from the scorching hot surface and caustic chemicals. Regular latex gloves will melt in an instant.

- Safety Goggles: A tiny splash of a high-pH cleaner in an eye can cause permanent damage. Goggles that create a full seal around the eyes are an absolute must.

- Waterproof Apron: This is a simple but effective barrier, protecting skin and clothing from chemical spills and hot, greasy splashes.

Griddles get hammered with grease all day, every day, which is why cleaning them properly is so vital for both health and safety. The commercial kitchen cleaning services market is a massive USD 385.7 million global industry for this very reason, with restaurants making up about 47.6% of that market because of strict health regulations. You can find more details about this market by exploring these professional cleaning service market insights.

At the end of the day, creating a safe kitchen is all about building good habits. By setting and enforcing strict protocols for handling and storing your restaurant cleaning supplies, you create an environment where safety becomes second nature.

Frequently Asked Questions About Griddle Cleaning

Even with the best system in place, questions are going to pop up. Commercial kitchens are breeding grounds for myths and so-called shortcuts, especially when it comes to cleaning the griddle. We've heard them all, so let's set the record straight.

Getting clear answers not only solves your immediate problem but also helps your whole team stick to the best practices. This keeps your equipment safe and your food quality high. Think of this as your go-to guide for busting myths and keeping that griddle in prime condition for years.

Can I Use Ice to Clean My Commercial Griddle?

We see this one all the time, and the answer is a hard no. Throwing ice on a blazing hot griddle is called "thermal shocking." Sure, the sizzle and steam look like they're doing something, but it’s a shortcut that can cause serious, permanent damage to your equipment.

That extreme, sudden temperature drop can cause the thick steel or chrome plate to warp, bow, or even crack. A warped griddle means uneven heat, hot spots, and inconsistent cooking forever. It's just not worth it.

Professionals will tell you to never use ice. It’s far safer—and more effective—to use proper high-temperature restaurant cleaning supplies while the surface is still hot. Protecting your equipment is a much smarter investment than saving a few minutes on cleanup.

How Often Should I Season My Steel Flat Top Griddle?

This really depends on the kind of cleaning you’re doing. After a routine daily scrub—scraping, degreasing, and wiping it down—you’ll want to do a quick re-seasoning. This simple step keeps that protective, non-stick patina in good shape, preventing rust and making sure food releases easily.

But after a deep clean, where you’ve used heavy-duty carbon removers to strip the surface down to the bare metal, you’ll need to do a full, thorough seasoning. This builds that protective layer back up from scratch. Of course, any brand-new steel griddle needs an intensive seasoning before you ever cook on it.

What Is the Difference Between Cleaning Steel and Chrome Griddles?

Knowing the difference here is non-negotiable. Using the wrong tools or chemicals on the wrong surface can destroy a griddle in seconds. Steel and chrome require totally different cleaning methods.

-

Steel Griddles: These are your classic, rugged workhorses. Their porous surface can handle a beating from aggressive tools like griddle bricks, screens, and pumice stones. They absolutely must be seasoned with oil after every deep clean to build that non-stick layer and prevent rust.

-

Chrome Griddles: These have a delicate, non-porous plating that creates a naturally non-stick finish. You must NEVER use abrasive tools like griddle screens or bricks on chrome. They will scratch and permanently ruin the plating. Only use non-abrasive pads and cleaners specifically designed for chrome surfaces. They do not need to be seasoned.

Mistaking one for the other is an expensive mistake. Always double-check what type of griddle you have and stick to the right tools for the job. It's a simple step that guarantees your griddle performs the way it should and lasts for the long haul.

Ready to build the perfect cleaning toolkit for your kitchen's workhorse? Griddles.com offers a curated selection of commercial griddles and the essential line equipment to keep your operation running smoothly. Find reliable, value-forward equipment.